Pressure Sensors by Applied Measurements UK Manufacturer

Applied Measurements design, manufacture and supply high-precision pressure sensors many of which can be bought online.

Our pressure sensors deliver high precision in a vast range of media and applications such as wastewater, sewage and ballast tanks. They can be used in low-range applications from as low as 0.25mbar to high-range pressures up to 0-6000 bar. We offer high-temperature options up to 250°C and ATEX intrinsically safe versions.

Product Links

Filters

Availability

Media

Output

Environment

Pressure Range

Accuracy

OEM Pressure Sensors

0-25mbar up to 0-6000bar+From Speak to Sales

What are Pressure Sensors?

Typically, pressure sensors (sometimes called pressure transducers or pressure transmitters) are used to measure the pressure of fluids (gases or liquids). Pressure is an expression of the force required to stop a fluid from expanding and is usually stated in terms of force per unit area.

Pressure Sensors Explained

Pressure Sensor Design

A pressure sensor generates an electrical signal relating to the pressure imposed. Such a signal is normally digital or analogue, although optical, visual and auditory signals are also common.

Industrial pressure sensors also referred to as pressure transducers, pressure transmitters, pressure indicators and pressure switches, normally have a diaphragm-type design that uses strain gauges, which are either bonded to or diffused into it, with the strain gauges acting as resistive elements. Under the pressure-induced strain, the resistive values change. In capacitive technology, the pressure diaphragm is a single plate of a capacitor that changes its value under pressure-induced displacement, see the cross-section diagram below.

Pressure sensing using diaphragm technology measures the difference in pressure between the two sides of the diaphragm. Depending on the relevant pressure, the terms ‘Absolute’ is used when the reference is vacuum; ‘Gauge’ (also known as ‘gage’) is used where the reference is atmospheric pressure; and ‘Differential’ is used where the sensor has two ports for the measurement of two different pressures.

Pressure sensors are used in various applications for control and monitoring purposes. They can also be used to indirectly measure other variables such as fluid flow, speed, water level and altitude.

Pressure sensors vary considerably in their design, technology used, performance, application and cost. Worldwide, hundreds of different technologies are used in pressure sensor designs and thousands of different suppliers of pressure sensors.

Certain types of pressure sensors are designed to measure dynamically and are able to capture very high-speed changes in pressure. Example applications here are in the measurement of combustion pressures in engine cylinders or gas turbines. These sensors are normally manufactured using piezoelectric materials such as quartz.

Some pressure sensors operate using a binary method. In this design, when pressure is applied to a pressure sensor, the sensor completes or breaks an electrical circuit. These types of sensors are also referred to as pressure switches.

What is the Best Pressure Sensor?

Choosing the best pressure sensor really does depend on the type of application, the process media and the measuring range. Additional factors that will help you decide what is the best pressure sensor for your application could include the accuracy needed, the application environment and the measuring type i.e. absolute, gauge, vacuum, differential and sealed pressure sensors.

Temperature and output can also be factors in helping you choose the best pressure sensor type for your application. Below are some of the pressure sensor types Applied Measurements can offer you. As always, our technical team are available to help you choose the best pressure sensor for your application if you’re unsure or need expert guidance on any aspect.

Types of Pressure Sensors

Pressure sensors can be classified in terms of the pressure range they are measuring, the operating temperature range, or the type of pressure they are measuring. In terms of pressure types, pressure sensors can be divided into several main categories:

Absolute Pressure Sensors

An absolute pressure sensor measures the pressure relative to perfect vacuum pressure (0 PSI or no pressure). Atmospheric pressure is 101.325 kPa (14.7 PSI) at sea level with reference to vacuum.

Gauge Pressure Sensors

A gauge pressure sensor is used in different applications because it can be calibrated to measure the pressure relative to a given atmospheric pressure at a given location. A tyre pressure gauge is an example of gauge pressure indication.

Vacuum Pressure Sensors

A vacuum pressure sensor is used to measure pressure less than the atmospheric pressure at a given location and is also known as negative pressure.

Differential Pressure Sensors

These sensors measure the difference between two or more pressures introduced as inputs to the sensing unit. For example, measuring the pressure drop across an oil filter. Differential pressure is also used to measure flow or level in pressurised vessels.

Sealed Pressure Sensors

A sealed pressure sensor is similar to the gauge pressure sensor, except that it has already been calibrated by the manufacturer to measure pressure relative to sea level pressure.

How to Choose a Pressure Sensor

The below are important factors when choosing a pressure sensor for your application.

- Pressure Media

- Pressure Temperature

- Operating Environment

- Pressure Range to be Measured

- Accuracy Level

- Electrical Output Signal

- Process Connection Type

- Electrical Connection Type

1) Pressure Media

Firstly, you need to know the type of media the pressure sensor will be operating in. For example, liquid, gases, fuel, viscous media, and oxygen. This will determine what type of pressure sensor would work best in those conditions. Applied Measurements can supply flush diaphragm pressure sensors that operate in viscous media, oxygen-ready pressure sensors and shipbuilding-regulated pressure sensors, plus many others.

2) Pressure Temperature

The temperature of the media the pressure sensor will be operating in also needs to be considered. Applied Measurements can supply pressure sensors that can work in temperatures of up to 250°C!

3) Operating Environment

Determine the environmental conditions where the pressure sensor will be installed. Factors such as temperature extremes, humidity, corrosive substances, or potentially explosive atmospheres will influence the type of pressure sensor that will be suitable for specific environmental protections.

4) Pressure Range

Having a defined pressure range will determine the models of pressure sensor sensor available for your application. It is also important to consider the risks of over-pressurisation, which could be due to a system malfunction, a value opening or closing (which typically cause pressure spikes or transients), or one of various other phenomena, and to ensure that your chosen pressure sensor will cope with them.

5) Accuracy Level

Define the required level of accuracy for your application. Different sensors have varying levels of accuracy, so choose one that meets the precision needed for your specific use.

6) Electrical Output Signal

The electrical output signal of the pressure sensor needs to be compatible with your pressure measuring system. Common output types include analogue (e.g., voltage, current), digital (e.g., I2C, SPI), or frequency-based signals. Select one that integrates seamlessly with your control or monitoring system.

7) Process Connection Type

Process connection will depend on how the pressure sensor will be integrated into your system. Options include threaded, flanged, welded, or other specialised connections. Applied Measurements technical team can provide guidance on the various options available.

8) Electrical Connection Type

Consider the electrical connection type that aligns with your system’s requirements, such as connectors, cables, or wiring connections.

If in doubt, on any of the above and you would like some advice, ask the experts. Here at Applied Measurements, our UK-based technical team is always on hand to provide guidance.

Technologies Used in Pressure Sensors

Strain Gauge

Strain gauge or foil gauge technology makes use of the changes in resistance that some materials experience due to change in their stretch or strain. Here, the technology uses the change of conductivity of material when it experiences different pressures and calculates that difference, then maps it to the change of pressure.

A strain gauge is a long length of conductor arranged in a zigzag pattern on a membrane. When it is stretched, its resistance increases. Strain gauges are mounted in the same direction as the strain and often in fours to form a full ‘Wheatstone Bridge’. A pressure sensor can contain several similar strain gauge elements.

Fibre Optic

This technology uses the properties of fibre optics to affect the light propagating in fibre, such that it can be used to form sensors. Pressure sensors can be made by using miniature fibre optic interferometers to sense the nanometer-scale displacement of membranes. Pressure can also be made to induce loss into a fibre to form intensity-based sensors.

Mechanical Deflection

This technology uses the mechanical properties of a liquid to measure its pressure. For example, the effect of pressure on a spring system and the changes in compression of a spring can be used to measure pressure.

Semiconductor Piezoresistive

To measure pressure, this technology uses the change in conductivity of semiconductors due to the change in pressure.

Microelectromechanical Systems (MEMS)

Here, the technology combines microelectronics with miniature mechanical systems such as valves and gears, all on a single semiconductor chip using nanotechnology to measure pressure.

Vibrating Elements (e.g. silicon resonance)

To calculate the pressure, vibrating elements are used to gauge the change in vibration on a molecular level of the different material elements due to changes in pressure.

Variable Capacitance

This technology uses the change of capacitance due to the change in the distance between the plates of a capacitor because of the change in pressure to calculate the pressure.

Pressure Sensor Applications

Pressure Sensing

Pressure sensors are used in a wide variety of applications. When used directly to measure pressure, applications include weather instrumentation, aerospace and defence, research and development, automotive and many other machinery or equipment that has pressure functionality implemented.

They can be used in hydraulic systems, water depth, pneumatics, marine, sewage, gas, medical, food and beverage processing, tank level/contents, HVAC systems, agricultural equipment, aerospace and chemicals.

Other notable versions are common, including high-temperature, three-in-one, ATEX-certified, hygienic and field-adjustable pressure sensors. Ceramic pressure capsules, low-cost foil strain gauge type, depth/level transmitters, and differential pressure transmitters (wet/wet type and dry air/gas type) are other popular variations.

Flow Sensing

Here, pressure sensors utilise the Venturi Effect in order to measure the flow. Differential pressure is measured between two segments of a Venturi tube that have different apertures. The pressure difference between the two segments is directly proportional to the flow rate through the Venturi tube. A low-capacity pressure sensor is almost always required as the pressure difference is relatively small.

Altitude Sensing

This is useful in commercial and military aircraft, rockets, satellites and weather instrumentation. These types of applications all make use of the relationship between changes in pressure relative to the altitude.

Case Studies

5 Reasons to Use Our Pressure Sensors in Your Diesel Injector Tester

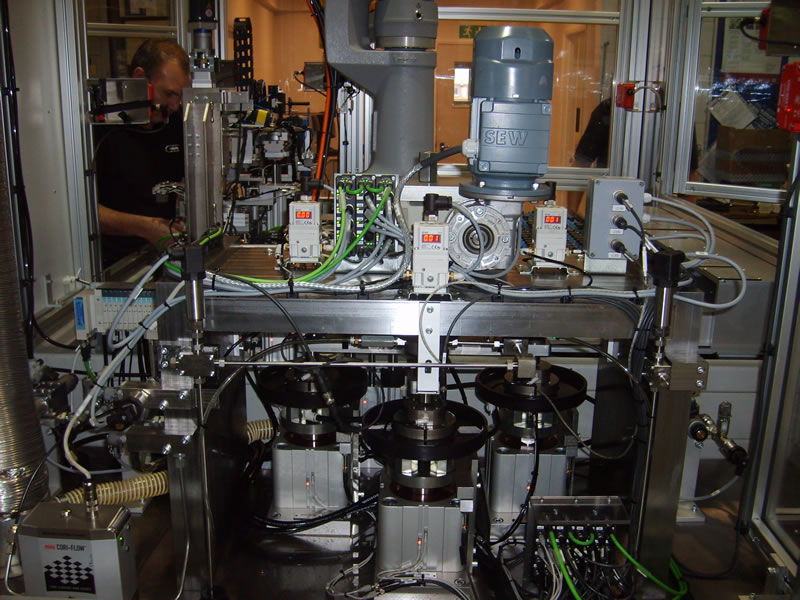

Curtis Assemble & Test Ltd, a designer and manufacturer of high-performance automotive test machines, use our pi600 industrial pressure sensors in their diesel injector valve pressure tester. “We choose to use Applied Measurements pressure transducers on our machines due to the reliability and competitive pricing. For us they are a fit and forget part,” explains Mark Hobday, Technical Development Engineer, Curtis Assemble & Test Ltd.

Why United Utilities Chose Us To Keep The Water Flowing

United Utilities needed a way to monitor the constantly changing water level in their water treatment plant to guarantee a steady flow of water into the reservoir. Learn how they did it using our level transmitters.

Pressure Transducer Delivers Water Level Monitoring in Emergency Tank Shower

Applied Measurements provided spill control and containment manufacturer Empteezy with a Pi600 series pressure transducer. The Pi600 series pressure transducer was connected and calibrated to the digital readout scale on the front of the shower giving an accurate reading of the litres of water remaining in the tank.

Interested in our pressure measurement products? Let us call you…

Why Choose Applied Measurements?

- Applied Measurements are suppliers of top quality transducers to every corner of industry – UK and worldwide

- Applied Measurements have over 100 years of expert transducer knowledge

- Applied Measurements high-quality products all come with a 3 year warranty