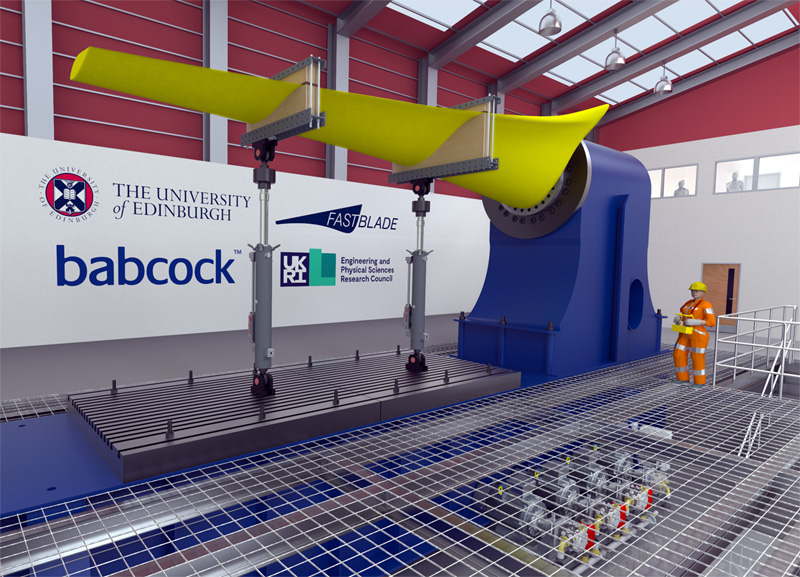

Applied Measurements Load Cells in FASTBLADE Fatigue Test Facility

Developed by the University of Edinburgh, FASTBLADE is designed for high-quality, low-cost fatigue testing of tidal turbine blades, composite bridge sections and carbon fibre aircraft wing boxes and is the world’s first test facility that uses regenerative hydraulic technology.

Thanks to its cost-effective and accelerated testing, FASTBLADE reduces design risks, delivers rapid evaluation and enables faster certification and deployment of new products to the global market.

Applied Measurements Precision Pancake Load Cells

Key Features:

- Capacities: 0-5kN up to 0-1000kN

- Output: 2mV/V

- High-Frequency Response

- Superb Accuracy <±0.05%

- IP65 Splash-Proof Protection

- IP67 Gel-Filled & IP68 Submersible Versions Optional

- Fatigued Rated Versions

- Bespoke Versions

Applied Measurements DSCC precision pancake load cells are an integral part of FASTBLADE’s design. They are low profile, high accuracy and have a high-frequency response. As standard, our DSCC pancake load cells have a superb accuracy of less than ±0.05% of rated capacity and thanks to their central threaded through-hole, the effects of any off-axis loading and bending are kept to a minimum.

Our low profile pancake load cells can accurately measure in both tension and compression, plus we can provide optional rod ends and load buttons to further enhance their performance.

The DSCC pancake load cell can be easily customised with gel-filled to IP67 and IP68 submersible protection ratings for subsea and harsh environments along with specific dimensions, alternative threads and mounting holes to suit your needs.

For FASTBLADE we supplied specific fatigue rated pancake load cells with custom through holes and a mounting base suitable for mounting their existing accelerometer. An integral ICA4H amplifier was fitted in a square boss housing, delivering a 4-20mA output, along with a 6-pin MIL-spec connector and a 25m mating cable assembly.

Our pancake load cells are fitted between the end of FOX-VPS Servo Actuators piston rod and a swivel bearing that is attached to the test article. Both sides of the attachment have high tensile studs screwed into the pancake load cell which are pre-loaded by screw jacking plates to eliminate the effects of fatigue.

We are proud to have been part of such an important and inspiring project that will help to bring new innovative products to the market.

If you have any exciting projects you would like to discuss with us, please call John or Simon in our technical sales team on (+44) 0118 981 7339 or email [email protected] and they will get straight back to you.