Full Design, Bonding & Wiring Service

- Dedicated UK-Based In-House Bonding Room

- Guidance and Advice from our Expert Team of Strain Gauge Engineers

- Full Design, Bonding & Wiring Service

- One-Off or High Volume

- Urgent Delivery Options

- Temperature Compensation

- Protective Coatings

- Signal Conditioning Integration

- Special Environmental Protection Options up to IP68 (Fully Submersible)

- UKAS Traceable Calibration

Why Us?

We have over 100 years of transducer design and application experience, plus over 95 years of strain gauge bonding experience. Our strain gauging team have bonded more than one million strain gauges and we’re still counting.

We can offer you fast, expert advice on your specific application, via phone or email as you prefer, with unparalleled aftersales service and technical support. Get a sensor tailored to your exact requirement, whether you want one unit or thousands. We offer superb quality and performance all backed up with our ISO 9001:2015 Certification.

Dedicated In-House Bonding Room

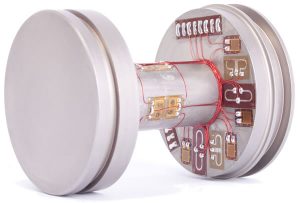

We know that the quality of the strain gauge installation greatly influences the accuracy of the final results. Strain gauges can only measure material strain accurately, consistently and reliably if they are intimately and expertly bonded to the surface.

That’s where we come in. Our in-house team of strain gauge specialists offer a full design, bonding and wiring service from one-off projects through to high-volume applications. Our UK-based on-site strain gauge room is continually monitored throughout to ensure top quality and high precision.

Our On-Site Strain Gauging Facility

Our on-site temperature-controlled strain gauge bonding room has a steady temperature, humidity and airflow to give optimum ambient conditions for strain gauge work at all times.

Strict ultrasonic cleaning procedures and surface preparation processes ensure that dust and dirt particles cannot contaminate the substrate onto which the strain gauges will be placed. Bonding is carried out immediately after the surface has been cleaned to ensure a flawless bond between the strain gauge and the sensing surface. These procedures are coupled with high-accuracy marking techniques and microscopes to guarantee the precise positioning of the strain gauges and give the best possible sensing performance.

Special adhesives are used depending on the material, type of strain gauge and environmental conditions of your application. Recommendations by our expert strain gauge team will be discussed with you before the process begins.

Strain Gauge Services and Options Available

- Full, Half & Quarter Bridge Configurations

- Heat Treatment and Stress-Relieving of Metalwork

- Bead Blasting and Anodising

- Metalwork Preparation, Modification and Machining

- Temperature Compensation

- Bridge Balancing

- Shunt Calibration

- Testing and Calibration (load/force, weight, torque and pressure)

- Protective Coatings for Various Environments

- Protective Housings for Fully Submersible Applications

- Signal Conditioning Integration

- Wireless Telemetry Integration

- High-Temperature Versions for use 200°C+!

Strain Gauge Design Consultation

We offer a complete bridge design, strain gauge bonding and wiring service to suit your specific application. Our engineers are available to discuss your requirements by telephone +44 (0) 1189 817 339, email or in person as you prefer. We can bond and wire strain gauges onto your own free-issued components and undertake the work to modify them if required.

Interested in this service? Let us call you...