Applied Measurements have been supplying top-quality strain gauge sensors and transducers to every corner of industry from aerospace, geotechnical, and subsea to R&D for over 30 years. Our team boasts more than 100 years of transducer experience and application knowledge so we can supply you with your ideal sensor or system.

Plus, since February 2018 Applied Measurements are now ISO 9001:2015 Quality Management Certified by BSI under certificate number FS 677584 for the design, manufacture and distribution of transducers and measuring systems. Read more about our ISO 9001 certification.

Applied Measurements are proud to announce that since February 2023 we are Cyber Essentials Certified. Cyber Essentials is a government-backed scheme that helps to protect an organisation against a wide range of the most common cyber attacks. Read more about our Cyber Essentials Certification.

Combining that with our expert advice and after-sales service means we do all the hard work to make sure that you get the very best out of your sensor or system, so you don't have to.

We are based in Berkshire, Southern England and supply not only to the UK but worldwide as well. Can we help you too?

Meet the team who make it happen...

Directors

Ollie Morcom

Sales Director

Darren Skipp

Commercial DirectorManagers

Lee Holloway

Production Planner

Chris Rebbeck

Gauging Supervisor

Paul Jones

Production Manager of the Pressure DepartmentSALES, Administration & Marketing

Sam Hayler

Technical Sales Engineer

Caroline Clark

Administration

Liz Turton

Administration

Molly Ginns

Sales & Service Administrator

Ian Wooldridge

Administration

Karen Jones

Accounting

Candice Haines

Internal Sales Administrator

Andre Alford

Marketing AssistantProduction

Our team of technicians are dedicated and expertly trained in the manufacture and calibration of all our sensors and instrumentation.

James

Systems Engineer

Dan Davies

Production Assistant

Sam Pike

Technician

Judit Straub

Production Engineer

Dave Hudson

Production Engineer

Ian Barlow

Technician

Joanna Zablocka

Production Planner

Andy Ritchie

Production Engineer

Marcin Jakubowski

Production TechnicianOur team of strain gauge technicians perform the precise, high-quality strain gauge bonding that is core to all of our products.

Helen Stevens

Strain Gauge Technician

Honey Nethercliffe

Strain Gauge Technician

Lyn

Strain Gauge Technician

Dave

Production EngineerOur team of pressure technicians produce precise, top-quality pressure sensors from one-off to high volume.

Romeo Raffai

Pressure Technician

Sarah Quelch

Pressure Technician

Paul Sydenham

Pressure Technician

Wioletta Wojcik

Pressure Technician

Alan Burgess

Pressure TechnicianHigh Quality

All of our load cells, force sensors and torque transducers are either manufactured from specially selected high grade stainless steel, heat treated for maximum stability, high strength aircraft grade aluminium alloy or alloy steel with nickel-plating for maximum environmental protection.

Construction utilises premium quality, transducer class strain gauges, which are bonded by hand to the specially prepared surfaces of the load cell element. Strain gauge bonding is carried out in strictly controlled clean room conditions to ensure a first class product.

Warranty

Our faith in the high quality and reliability of our products is supported by the standard 3-YEAR WARRANTY provided with every product in our range.

Testimonials

Our knowledgeable team of engineers with their wealth of experience within the transducer industry will be pleased to assist with the definition of your application requirements and the meeting of these needs. Our policy is to supply standard products from stock where possible, or on a scheduled basis if that is what you need, with custom designed units being supplied in a timely manner.

Don't take our word for it, read what our existing customers say about us:

We have been working with Applied for more than 20 years and our customers have been enjoying the three Qs, i.e. Quality in equipment, Quality in Support and Quality in Services! Applied have managed to make themselves better and better over time!

Paris Xystris, NEOTEK OE P. XYSTRIS & Co, Athens - Greece.

Applied Measurements’ delivery times for both standard and custom-built products are excellent. As is their prompt customer service and technical support.

Davide Pignoli - LEANE International S.r.l. - Italy.

We have worked with Applied Measurements for probably the full 23 years! We have always found Peter, Darren, Ollie, and everyone else at Applied Measurements to be extremely friendly, reactive, and professional in their approach. The quality of the instruments and the service is always very good.

Karl Snelling at GDS Instruments, UK.

My confidence in their ability to provide a solution for my custom force measuring requirements has resulted in Applied Measurements being my preferred supplier. I would recommend them to anyone looking for not only force measurements but any standard or bespoke measuring devices that they supply.

Gary Sharpe, Safran Electrical & Power UK Ltd

We have used and supplied thousands of Applied Measurement load cells over the last 18 years and the flawless product performance is matched by excellent technical and commercial support, think force accuracy, think AML

A prominent force measurement company.

Customers and Case Studies

Applied Measurements' customer base is as varied as the range of products that are available and include some very prestigious companies: Airbus UK, British Aerospace, British Gas, Burmah Castrol, Dairy Crest, ESR Technology, Ford Motor Company, GEC, GKN, ICI, Jordan Cereals, Kellogg Company, Lucas Aerospace, McLaren Automotive, NASA Jet Propulsion, Nuclear Electric, Pirelli Cables, Red Bull Technology, Rolls Royce, Safran Electrical & Power UK Ltd and most of the major UK water authorities.

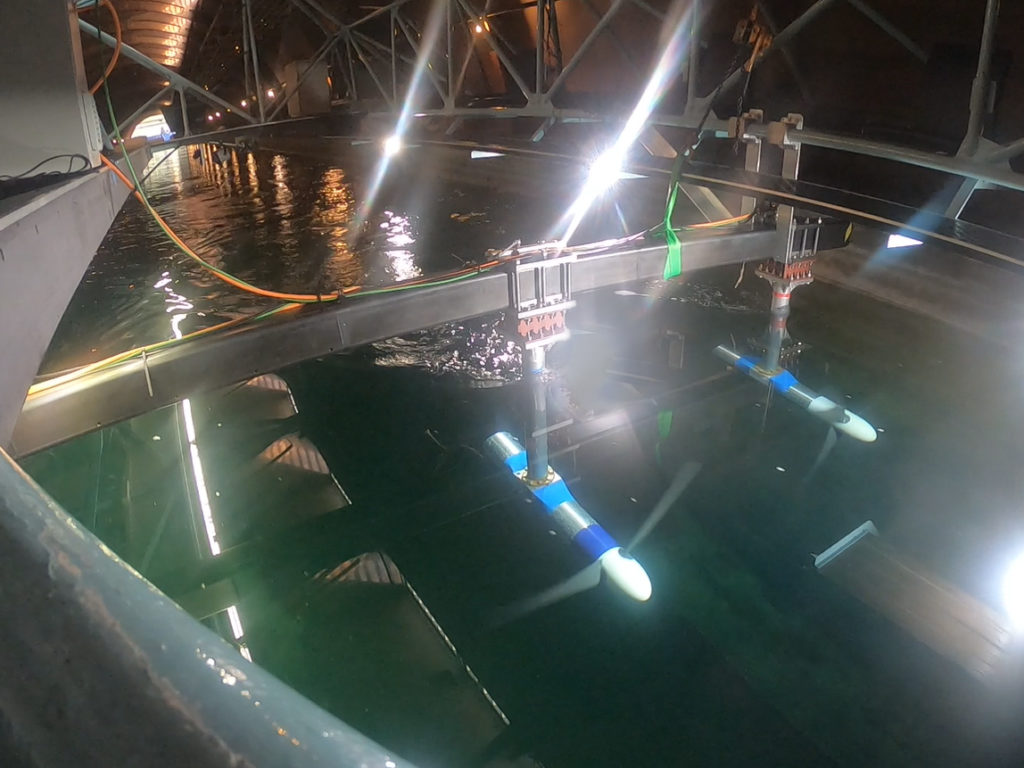

Precise Thrust & Torque Results in Tidal Turbine Testing

Applied Measurements was approached by The Tidal and Wind Energy Research Group at the University of Oxford which wanted to measure the constructive interference effects on tidal turbines. For this tidal application, we designed a dual-axis force and torque sensor with bespoke dimensions to fit the customer’s own housing and own connector. Plus, we customised the sensor to IP68 fully submersible rating, once installed, to guarantee its performance underwater.

High Accuracy Load Cells for the Gemini Telescopes

Applied Measurements were proud to be selected by the Royal Greenwich Observatory as the load cell supplier for the two Gemini Telescopes. This project involved the development of special very high accuracy load cells, which pushed the boundaries of load cell technology to their limits and involved the manufacture of some 750 sensors as part of a £500,000 contract. This was delivered precisely on time and met one hundred per cent the customer's specified requirements.

Sub-Zero Temperature Ice Core Drilling in the Antarctic

We provided the RICE (Roosevelt Island Climate Evolution) Team with modified shear load pin cells which could operate reliably and accurately in the sub-zero temperatures of the Antarctic. The successful drilling of the 763m deep ice core from Antarctica demonstrates beyond doubt the reliability of our products in extreme sub-zero temperatures.

Creating 1000 Times More Power With Permanently Submersible Load Pins and Pancake Load Cell

Our expert team of engineers designed and manufactured a fully customised DBEP load pin and DSCC pancake load cell for Minesto's tidal energy application. The sensors had to be fully submersible, lightweight and small enough to fit into their existing underwater kite assembly and control units.

Automotive Industry Multi-Channel Weighing System

We designed a multi-channel weighing system to measure the centre of mass of a bus, which is a critical part in vehicle design and engineering for Plaxton (a coach and bus manufacturer). This system was custom designed by our engineers for Plaxton's specific application requirements.

See how we can customise sensors for your project