Berkshire, UK bespoke Load Cell

- Simple 5-Step Load Cell Design Process

- Expert Team of UK Engineers

- Aldermaston, Berkshire-Based In-House Design Service

- Minor Modifications to Fully Bespoke Products

- One-Off to High-Volume

- Delivery Dates to Suit You

- All Industries, All Environments & Any Application

- Ideal Designs at Reasonable Costs

- High & Low Capacities

- Instrumentation Available for a Complete Monitoring System

Load Cell Design

We know how costly and time-consuming it can be to fit your design around a standard product. Or perhaps you need something retrofitted into an existing design or the original replacement parts are no longer available.

We are based in Aldermaston, Berkshire and can manufacture and deliver throughout the UK and globally.

Our UK-based engineers have been experts in custom load cell design and bespoke systems for over 30 years. Many of our standard products can be readily modified and some can even be fully customised to suit your exact requirements. Whether that be changing the dimensions, making it completely submersible or adapting it for use in extreme temperatures. And if something doesn’t fit the bill, we can even design and manufacture a completely new product from scratch specifically for your application.

Throughout the last 30 years, we have made one-off products to high volume batch production, all without unreasonable costs and all to the customer’s delivery schedule.

In-House Design Service

Our expert team of engineers are on-site in Aldermaston, Berkshire and our custom load cell design service is all done in-house. We use the latest computer-aided design software (CAD) which replaces the manual drafting of drawings with a faster and more accurate up-to-date process.

This CAD software optimises the creation and design of your bespoke product and ensures easy modification and analysis. What’s more, the CAD drawings are all done in-house by our specialist design team so referring back to the designs in the future can be done quickly and easily.

See our 3D STEP files page to view the recent 3D models of our standard products, FREE to download.

Manufacture & Production

Once you have approved the design we will begin production of your customised sensor. Take advantage of our high-quality and expert engineers with their wealth of technical knowledge to build your unique product. We can build one-offs to high volume using the latest up-to-date facilities.

Plus, we have a UK-based in-house strain gauging team so we can keep control of all aspects of your production. Be assured that your customised product will be thoroughly quality-controlled throughout production and before delivery.

Take advantage of our various instrumentation such as digital indicators, displays, panel meters, and wireless radio telemetry, to support your customised product giving you a completely bespoke monitoring system. All our transducers and systems are calibrated and certified to UKAS traceable standards and come with a 3-year warranty as standard.

Examples of Our Custom Load Cell Design Service

Load cells deliver high accuracy in Gemini Telescopes even after 20 years!

20 years ago, we designed and manufactured over 700 bespoke load cells for 2 huge 8.1 diameter telescopes, known as The Gemini Project. Now 20 years on, these custom-made load cells are still consistently and accurately performing an integral part of the telescope’s control system. To continue to deliver accurate and detailed astronomical images, we re-designed and manufactured custom load cells to the same specifications incorporating up-to-date electronics with the latest state-of-the-art amplifiers.

Permanently Submersible Application – Converting Ocean Currents into Electricity

We designed and manufactured a permanently submersible DBEP load pin and DSCC pancake load cell to fit within Minesto’s Deep Green underwater kite assembly. The customised load pin matched their exact dimensions, was fully submersible and fitted with a polyurethane cable and submersible cable gland, guaranteeing long-term underwater use for the entire system. The DSCC pancake load cell was fully customised with customised dimensions, mounting holes, threads and a higher protection rating for long-term submersion in seawater.

Extreme Temperatures – Deep Ice Core Drilling in the Antarctic

DBEP shear pin load cells were modified for extreme temperatures as low as -30˚C using a high stability temperature compensated strain gauge bridge to minimise the effects of temperature. This enabled the Roosevelt Island Climate Evolution (RICE) team to successfully extract a 750m deep ice core from Roosevelt Island.

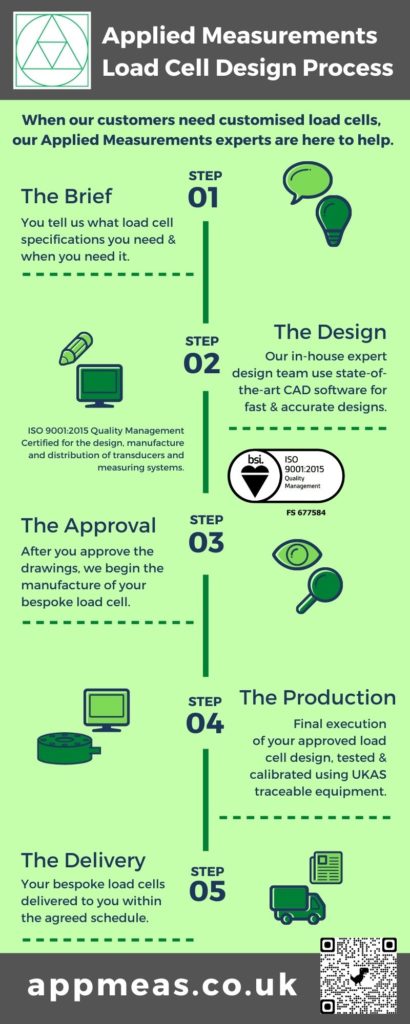

our 5 steps to load cell design

We believe in making our custom load cell design process as simple as possible, with these 5 easy steps.

Step 1 – The Brief

You tell us your application requirements, and we listen. We will assign you a specific member of our technical team who will use their vast load cell knowledge to make recommendations on your load cell design. Recommendations could include construction material, protection sealing, dimensions and appropriate installation.

Step 2 – The Design

Our in-house team of engineers use state-of-the-art computer-aided design software to deliver you a precision load cell design. Plus, all our load cell designs are created in-house, so they can be easily and quickly referred back to, saving precious design time.

Step 3 – The Approval

Only once you are 100% completely happy with your custom load cell design, will we begin the manufacturing process.

Step 4 – The Production

Your bespoke load cell is tested and calibrated using UKAS traceable equipment. Thanks to our on-site design and manufacturing facility, we have the capacity to manufacture one-off products to high volumes, giving you a greater choice of quantities and delivery times.

Plus, we are ISO 9001:2015 Quality Management Certified by BSI under certificate number FS 677584 for the design, manufacture and distribution of transducers and measuring systems. So, you can be safe in the knowledge that your customised load cell will be rigorously quality-controlled throughout its design and manufacture.

Step 5 – The Delivery

Your custom load cell will be delivered to you within the agreed schedule. Your design when you want it.

If that’s not enough, we’re so convinced of the high quality of our products, they ALL come with a FREE 3-year warranty!

Interested in this service? Let us call you...