250kN: 3 weeks (not DSCC8)

Over 250kN: 12 weeks

At a Glance

- Capacities: 0-5kN up to 0-1000kN

- Output: 2mV/V

- High-Frequency Response

- High Accuracy: <±0.05%/RC

- Options:

- Fatigue-Rated Versions

- IP67 Rated Versions

- IP68 Submersible Versions

- ISO 376 Version available

- Low Profile to Easily Fit Where Space is Limited

- Perfect for both Weighing and Force Measuring

- Ideal for Crash Test Walls

- High-Frequency Response

- Fully Submersible Marine and Underwater Versions Available

- Immersible Versions for Humid or Flood Risk Environments

- Customisation Available to Suit your Specific Application

- ISO 376 option available if you need to calibrate equipment

Description

The DSCC pancake load cell / low profile load cell by Applied Measurements is manufactured in stainless steel and is suitable for use in weighing and force measurement applications. Our pancake load cells are available to buy online with capacities 0-200kN in stock. Load buttons are also available on request.

The DSCC can operate in both tension and compression and are commonly used in materials testing and component fatigue testing applications for axial force measurements where a high accuracy, low-profile device is required.

The high-frequency response of the DSCC pancake load cells also makes them ideal for dynamic force and load measurement applications such as crash test walls. The high-speed analogue SGA amplifier is an ideal complement to the DSCC pancake load cell, offering a conditioned signal output of 4-20mA, ±5Vdc or ±10Vdc with a bandwidth of up to 6kHz.

Thanks to the pancake load cell’s dual-diaphragm design and central threaded through-hole, it is largely insensitive to bending, off-axis, bending, side-load/shear loads and torsion.

As with all Applied Measurements pancake load cell designs, the DSCC low profile load cell can be modified to suit your specific requirements, with alternative threads, custom dimensions, counter-bored mounting holes and higher capacities in excess of 3000kN possible.

Plus, for harsh, wet or humid environments we can make gel-filled pancake load cells rated to IP67. IP68 immersion versions are suitable for complete submersion and can also be offered on request. See Applied Measurements IP ratings guide for more details.

If you require a pancake load cell with a rated capacity below 5kN for low-range measurements, the DSCRC low profile load cell covers forces from 0-200N up to 0-2kN.

Our pancake load cell can be provided with Load Cell Instrumentation many of which are available to buy in our online shop.

ISO 376 Calibration standard

Our DSCCHA pancake load cell can be supplied with BS EN ISO 376 certification. ISO 376 certification is required if you wish your validated product to calibrate other products in accordance with ISO 7500. ISO 376 certification can be for compression, tensile or a combination of both. Please speak to our sales team for more details.

The ISO 376 compliant DSCCHA can also be supplied with a loading cap, and for tensile applications, Rod End Bearings.

Technical Specifications

| Rated Capacity (RC) | kN | 0-5, 0-10, 0-25, 0-50, 0-100, 0-200, 0-250, 0-300, 0-500, 0-750, 0-1000 |

|---|---|---|

| Operating Modes | Tension/Compression / Tension & Compression | |

| Sensitivity (RO) | mV/V | 2.0 (up to 200kN) / 2.7 nominal (250kN upwards) |

| Zero Balance/Offset | ±%/Rated Output | <1.0 |

| Output Symmetry (tension vs. compression) | %/Rated Load | <0.25 (0.8 typical on Ø155 250kN) |

| Non-Linearity | ±%/Rated Output (BFSL) | <0.05 (<0.03 typical) |

| Hysteresis | ±%/Rated Output | <0.05 (<0.03 typical) |

| Repeatability | ±%/Rated Output | <0.05 (<0.03 typical) |

| Temperature Effect on Zero | ±%/Rated Capacity/ ˚C | <0.005 |

| Temperature Effect on Sensitivity | ±%/Applied Load/ ˚C | <0.005 |

| Effect of Eccentricity | %/Applied Load/25mm | <±0.25 typical |

| Effect of Side Load | % | 0.25 typical |

| Bridge Resistance | Ohms | See dimension table |

| Insulation Resistance | Megohms @ 50 Vdc | >5000 |

| Excitation Voltage | Volts AC or DC | 10 recommended (2-15 acceptable) |

| Operating Temperature Range | ˚C | -20 to +80 |

| Compensated Temperature Range | ˚C | 0 to +70 |

| Storage Temperature Range | ˚C | -20 to +80 |

| Safe Overload | % of Rated Capacity | 150 |

| Ultimate Overload | % of Rated Capacity | >250 |

| Maximum Safe Side Load ** (Fx or Fy) | % of Rated Capacity | 40 |

| Maximum Safe Torque/Bending Moment | (Mx, My or Mz) ** | See dimensions table |

| Deflection @ Rated Capacity | mm (nominal) at Rated Load | 0.05 (>50kN) / 0.1 (100-250kN) / 0.13 (300-1000kN) |

| IP Rating (Environmental Protection) | IP65 | |

| Cable Length (as standard) | metres | 3 |

| Cable Type | Single Bridge Versions | 6-Pin Amphenol Connector (PT02A-10-6P to MIL-DTL-26482 spec) + Mating Cable Assembly (4-core screened cable, PUR sheath, Ø5) |

| Dual Bridge Versions | 8-Pin M12 x 1 Connector + Mating Cable Assembly, (8-core screened cable, PUR sheath, Ø^) | |

| Construction | Stainless Steel | |

| Resolution | 1 part in 250,000 (with appropriate instrumentation) | |

| Fatigue Life | Fully Reversed Cycles | Standard Versions: 30-50 million typical Fatigue-Rated Versions: 500 million Versions rated to 1 billion+ on request |

| *The resonant frequency is calculated with the body of the load cell attached to a large plate, ensuring that only the sensing element oscillates: This is vital to achieve the highest natural frequency and subsequent frequency response. | ||

| **Extraneous load ratings (Fx, Fy, Mx, My, Mz) are based on application of only one at any time in addition to force in the primary measurement axis (Fz). Contact our engineering department if multi extraneous loads will occur simultaneously. | ||

| CORE PRODUCT REF | CAPACITY (kN) | Bridge Resistance (ohms, nominal) | Deflection at RC (mm, nominal) | Resonant Frequency (kHz) | Extraneous Load Limit (Mx, My or Mz) (Nm) | Weight (kg no base) | Weight (kg with base) |

|---|---|---|---|---|---|---|---|

| DSCC | 0-5, 0-10, 0-25, 0-50 | 700 | 0.05 | 5kN=3.5 | 30 | 1.5 | 3.7 |

| 10kN=4.5 | 60 | ||||||

| 25kN=6.5 | 150 | ||||||

| 50kN=7.2 | 300 | ||||||

| DSCC | 0-100, 0-200, 0-250 | 1050 | 0.1 | 100kN=6.5 | 845 | 3.9 | 9.1 |

| 200kN=7.8 | 1690 | ||||||

| 250kN=8.7 | 2000 | ||||||

| DSCC8 | 0-250, 0-300, 0-500 | 1400 | 0.1 | 250kN=9 | 1500 | 11 | 24 |

| 300kN=9.3 | 1800 | ||||||

| 500kN=10 | 3000 | ||||||

| DSCC | 0-300, 0-500, 0-750, 0-1000 | 350 | 0.13 | 300kN=8.7 | 2030 | 25.5 | 65 |

| 500kN=8.9 | 3390 | ||||||

| 1000kN=9.0 | 6780 |

Product Dimensions

| Core Product Ref | CAPACITY (kN) | ØA (Size) | B | C | ØD | ØE | Thread F | ØG | N holes | H | J |

|---|---|---|---|---|---|---|---|---|---|---|---|

| DSCC | 0-5, 0-10, 0-25, 0-50 | 107 | 2 | 33 | 8.5 | 33 | M20 x 2.5 | 90 | 8 | 35 | 2 |

| DSCC | 0-100, 0-200, 0-250 | 155 | 3 | 45 | 11 | 60 | M36 x 2 | 130 | 12 | 45 | 2 |

| DSCC8 | 0-250, 0-300, 0-500 | 202 | 2 | 52 | 12.2 | 95.5 | M56x4 | 165 | 16 | 50 | 2 |

| DSCC | 0-300, 0-500, 0-750, 0-1000 | 278 | 6 | 78 | 17 | 118 | M64 x 6* | 230 | 16 | 84 | 4 |

| *If you require rod end bearings please request an M64 x 4 thread. Note that the maximum rated safe static load on this size rod end is 689kN. | |||||||||||

All dimensions are in mm

Wiring Details (Single Bridge Version)

| Wire | Connector Pin | Designation |

|---|---|---|

| Red | Pin A | +ve excitation |

| Blue | Pin B | -ve excitation |

| Green | Pin C | +ve signal (compression) |

| Yellow | Pin D | -ve signal |

| Screen | N/C | To ground - not connected to load cell body |

Wiring Details (Dual Bridge Version)

| Wire | Connector Pin | Designation |

|---|---|---|

| Red | Pin 8 | +ve excitation (bridge A) |

| Blue | Pin 7 | -ve excitation (bridge A) |

| Green | Pin 3 | +ve signal (compression) (bridge A) |

| Yellow | Pin 4 | -ve signal (bridge A) |

| Brown | Pin 2 | +ve excitation (bridge B) |

| White | Pin 1 | -ve excitation (bridge B) |

| Pink | Pin 6 | +ve signal (compression) (bridge B) |

| Grey | Pin 5 | -ve signal (compression) |

| Screen | N/C | To ground - not connected to load cell body |

Ordering Codes & Options

| Core Product | Capacity (inc Engineering Units) | Cable Length (m) | Specials Code | Example Result |

|---|---|---|---|---|

| DSCC | 5kN | 003 | 000 | DSCC-5kN-003-000 |

| DSCC | 10kN | 003 | 000 | DSCC-10kN-003-000 |

| DSCC | 25kN | 003 | 000 | DSCC-25kN-003-000 |

| DSCC | 50kN | 003 | 000 | DSCC-50kN-003-000 |

| DSCC | 100kN | 003 | 000 | DSCC-100kN-003-000 |

| DSCC | 200kN | 003 | 000 | DSCC-200kN-003-000 |

| DSCC | 250kN | 003 | 000 | DSCC-250kN-003-000 |

| DSCC | 300kN | 003 | 000 | DSCC-300kN-003-000 |

| DSCC | 500kN | 003 | 000 | DSCC-500kN-003-000 |

| DSCC | 750kN | 003 | 000 | DSCC-750kN-003-000 |

| DSCC | 1000kN | 003 | 000 | DSCC-1000kN-003-000 |

| DSCC8 | 250kN | 003 | 000 | DSCC8-250kN-003-000 |

| DSCC8 | 300kN | 003 | 000 | DSCC8-300kN-003-000 |

| DSCC8 | 500kN | 003 | 000 | DSCC8-500kN-003-000 |

| Other Specials Code | Details | |||

| 029 | Fatigue rated to 500 million cycles | |||

| 033 | Mounting base fitted | |||

| 061 | Fatigue rated to 500 million cycles + mounting base fitted | |||

| 088 | Dual strain gauge bridges + fatigue rated to 500 million cycles | |||

| 126 | Dual strain gauge bridges | |||

| 127 | Dual strain gauge bridges + mounting base fitted | |||

| 128 | Dual strain gauge bridge + mounting base + fatigue rated to 500 million cycles |

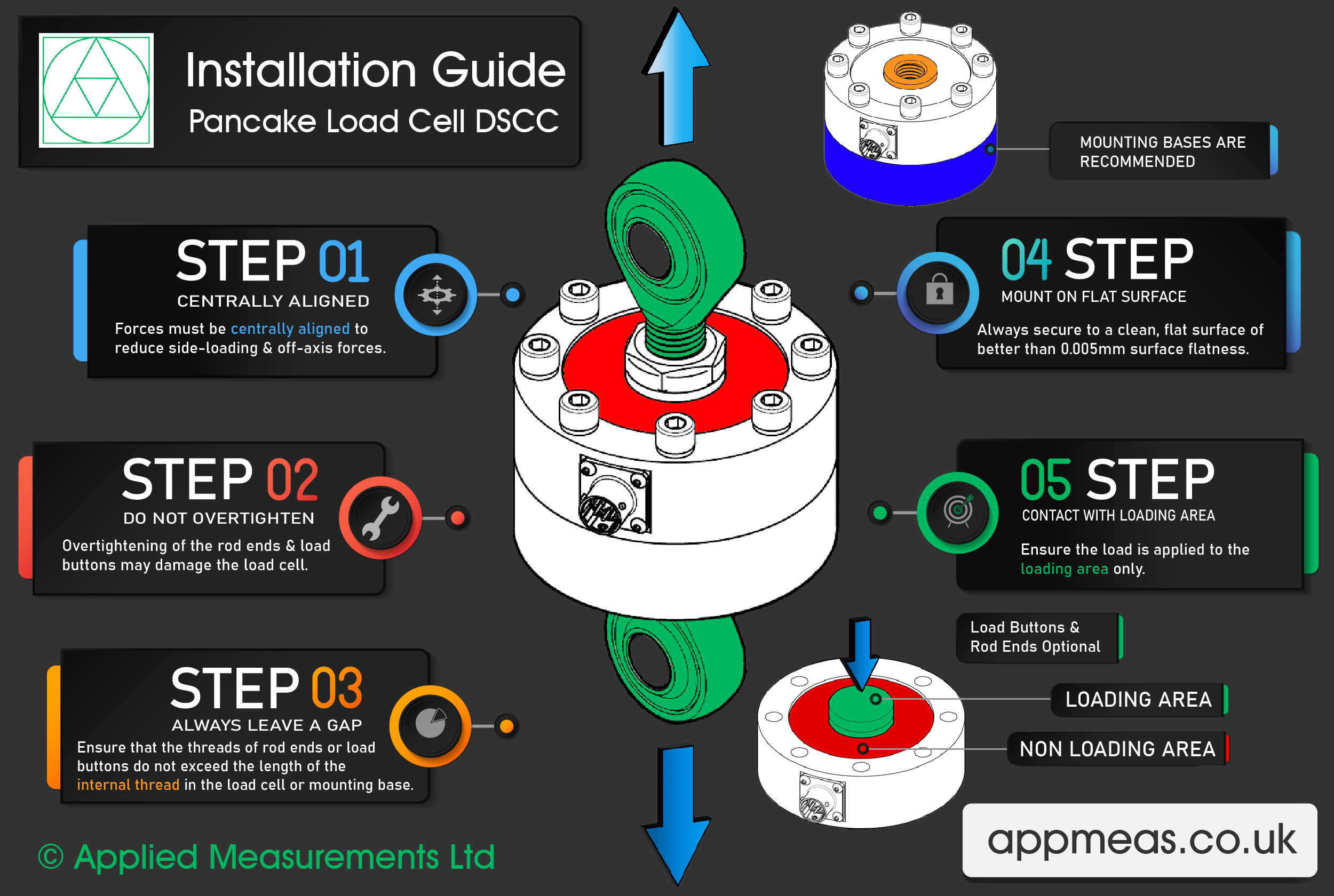

How to Install a Pancake Load Cell Guide

Our Applied Measurements experts have put together a 5-step guide to demonstrate how to correctly install a pancake load cell.

Step 1 – Keep the Forces Centrally Aligned

To reduce any off-axis loading, forces must be centrally aligned through the centre of the pancake load cell. We can supply optional load buttons and rod ends which work to reduce any side loading.

Step 2 – Do Not Overtighten the Rod Ends and Load Buttons

When using rod ends and load buttons be sure not to overtighten them when attaching them to the pancake load cell. As this can cause damage to the load cell.

Step 3 – Always Leave a Gap

Ensure that the threads of rod ends or load buttons do not exceed the length of the internal thread in the load cell or mounting base. If a gap is not maintained, the sensing section of the load cell will not be able to move freely when tensile or compressive force is applied, leading to erroneous readings and potential damage.

Step 4 – Mount on a Flat Surface

Always secure the pancake load cell to a clean, flat surface of better than 0.005mm surface flatness.

Step 5 – Contact with Loading Area Only

When installing the pancake load cell ensure the load is applied to the loading area only.

Mounting and Installation Accessories

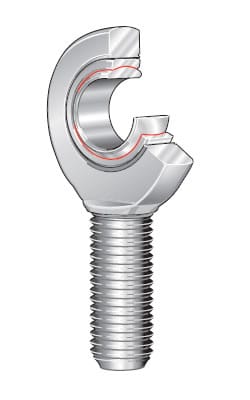

Load Buttons and Rod End Bearings

Designed to align forces through the principal axis of the load cell thus reducing the effects of extraneous forces, hence offering improved performance from the cell.

Load buttons are used where compressive forces are applied.

Rod End Bearings are used where tensile forces are being applied.

Load Buttons for Compressive Use

| THREAD T | M20 x 2.5 | M36 x 2 | M56 x 4 | M64 x 6 |

|---|---|---|---|---|

| D | 33 | 60 | 95.5 | 118 |

| H | 14 | 25 | 40 | 50 |

| L | 26 | 40 | 50 | 65 |

| R | 200 | 200 | 300 | 400 |

Rod End Bearings for Tension Use

Maintenance-free rod ends are a complete units made up of a housing with both an integral shank (with an internal or external thread) and a maintenance-free spherical plain bearing, located within the housing.

Rod End Series K – Maintenance Free – Series GAXSW – DSCC up to 200kN

For use at high tension loads up to 230kN. Consult sales for rod-end to suit DSCC-250kN.

Rod ends with male thread made from heat-treated steel, zinc plated with PTFE liner, maintenance free.

| Load Cell | Ordering Code | D | B | M | A | F | L | O | G | GL | Static Load C 0 kN | Dynamic Load C kN | Limiting Speed rev/min * | Weight g |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DSCC-5kN to 50kN | GAXSW20x2.5 | 20 | 25 | 18 | 50 | 78 | 103 | 24.3 | M20x2.5 | 47 | 93.5 | 78 | 190 | 348 |

| DSCC-100kN to 200kN | GAXSW35 | 35 | 43 | 28 | 80 | 125 | 165 | 37.7 | M36x2 | 73 | 230 | 205 | 110 | 1600 |

| For DSCC-250kN consult sales. | ||||||||||||||

| Materials: | |

|---|---|

| Housing | Heat-treated steel to 42CrMo4, Aisi 4140, forged. |

| Insert | Free-cutting steel to 9SMnPb28K, 12L13, with PTFE liner bonded to the inner surface. |

| Ball | Bearing steel to 100Cr6, Aisi 52100, hardened, ground, polished. |

Rod End Series GAR..UK-2RS – DSCC up to 1000kN (689kN max load*)

*Consult sales for rod-ends to suit forces over 689kN.

- Maintenance-free

- ISO 12 240-4, dimension series E, type M

- Sliding contact surface: hard chromium/PTFE

- Sliding material: Elgoglide®

GAR..UK-2RS

(right hand thread)

- To ISO 12 240-4, dimension series E, type M

- Shank with external thread

- Suffix -2RS: lip seals on both sides, for operating temperatures from -30°C to +130°C

| LOAD CELL | SHAFT DIAMETER | DESIGNATION | MASS | DIMENSIONS | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| d | WITHOUT SEALS | WITH SEALS | ≈ kg | d | D | B | dK | d1 | d2 | d3 | |

| DSCC-300kN to 1000kN | 80 | - | GAR 80 UK-2RS | 12 | 80-0.015 | 120 | 55-0.15 | 105 | 89.4 | 180 | M64 x 6 |

| DSCC8 0-250, 0-300, 0-500kN | 70 | - | GAR70-UK-2RS | 8.2 | 80-0.015 | 105 | 49-0.15 | 92 | 77.8 | 160 | M56 x 4 |

| LOAD CELL | Degrees | Chamfer Dimension | Basic Load Ratings 2) | Radial Internal Clearance | Shaft Diameter | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| h | C1 | α | l1 | l2 | l7 | r1s min. | dyn. Cr N | stat. C0r N | d | ||

| DSCC-300kN to 1000kN | 270 | 47 | 6 | 140 | 360 | 100 | 1 | 1 125 000 | 689 000 | 0 - 0.072 | 80 |

| DSCC8 0-250, 0-300, 0-500kN | 235 | 42 | 6 | 125 | 315 | 87 | 1 | 885 000 | 564 000 | 0 - 0.072 | 70 |

Downloads

CAD Model Files

Our 3D models are provided in STEP format and can be viewed using FreeCAD. Other formats can be provided on request.

The .zip file below contains a separate model for each product variant.

Instant Price & Part Code Builder

You can now buy this product in our online shop. Alternatively, you can find the ordering code, price* and lead time below.

Product Details

- Price*

- Lead Time

- Part Code

*Please note: The prices shown are valid in the UK only and do not include carriage charges. For overseas pricing please contact a member of our sales team or your local distributor.

Case Studies

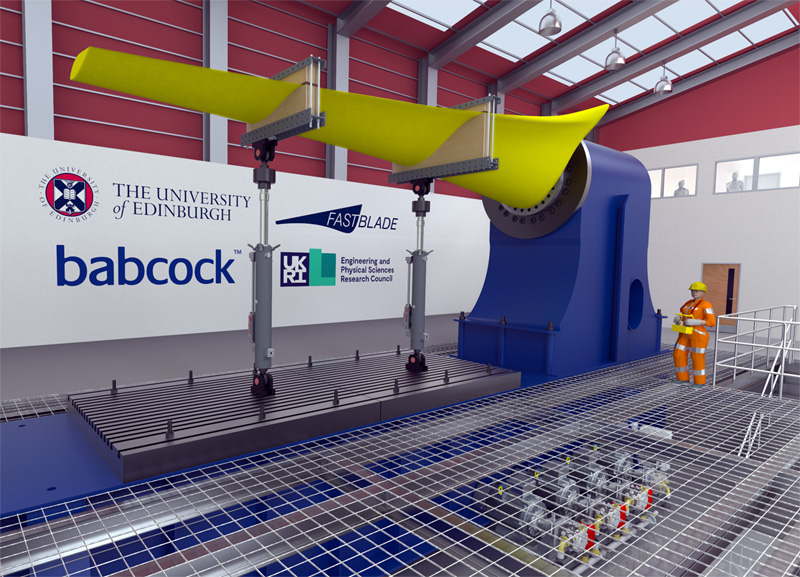

Applied Measurements Load Cells in World’s First Regenerative Fatigue Test Facility

Developed by the University of Edinburgh, FASTBLADE is designed for high-quality, low-cost fatigue testing of tidal turbine blades, composite bridge sections and carbon fibre aircraft wing boxes and is the world’s first test facility that uses regenerative hydraulic technology. Thanks to its cost-effective and accelerated testing, FASTBLADE reduces design risks, delivers rapid evaluation and enables faster certification and deployment of new products to the global market. Applied Measurements DSCC precision pancake load cells are an integral part of FASTBLADE’s design. They are low profile, high accuracy and have a high-frequency response. Find out more...

Creating 1000 Times More Power with Submersible Load Measuring Pins

The measuring device needed to withstand permanent underwater submersion. “Our load measuring pin’s stainless steel construction and ability to be customised to IP68 submersion rating made this the ideal choice for use in Deep Green’s control system”, explains Ollie Morcom, Applied Measurements’ Sales Director.

Applied Measurements’ Submersible Load Cells fitted to the World’s Largest All-Terrain Hexapod

Applied Measurements provided the load cells needed to monitor the force on individual legs to stop the Mantis (the world’s largest hydraulic hexapod robot) walking into a situation that is hazardous to its overall stability. Assisted by Applied Measurements’ compact and submersible DSCC load cells, the Mantis successfully travels over all slopes and uneven surfaces, traversing most types of terrain, even wading through water.

Why Applied Measurements?

- Suppliers of top quality strain gauge sensors and transducers to every corner of industry - UK and worldwide

- Over 100 years of expert transducer knowledge

- Our high quality products all come with a 3 year warranty

Popular Products

Platform Load Cell | Single Point Load Cell | 0-250g to 0-40kg | OBUG

0-250g to 0-40kgFrom £128Universal Load Cell | Universal S-Beam Force Sensor | DBBSM

0-1kg up to 0-30,000kgFrom £254Buy OnlineHandheld Load Cell Indicator | Digital Display | TR150

From £308Buy OnlineStrain Gauge Displacement Sensor | Linear Position Sensor | AML/SGD

0-5mm to 0-100mmFrom £425Buy Online