At a Glance

- Input: 0.06mV/V to 30.3mV/V

- Output: 0-5Vdc, 0-10Vdc, 4-20mA, 0-20mA, ±5Vdc or ±10Vdc

- Environmental Protection: IP67

- High Speed: Bandwidth 6kHz max.

- Mains & 18-24Vdc Versions

- Ideal for use in most Industrial Environments

- Dust Tight & Waterproof

- AC or DC Versions Available to Suit Your Specific Application

- Simple Setup – With Non-Interactive Span & Zero Controls

- Let Us Save You Time – We can calibrate it with any of our strain gauge transducers

Description

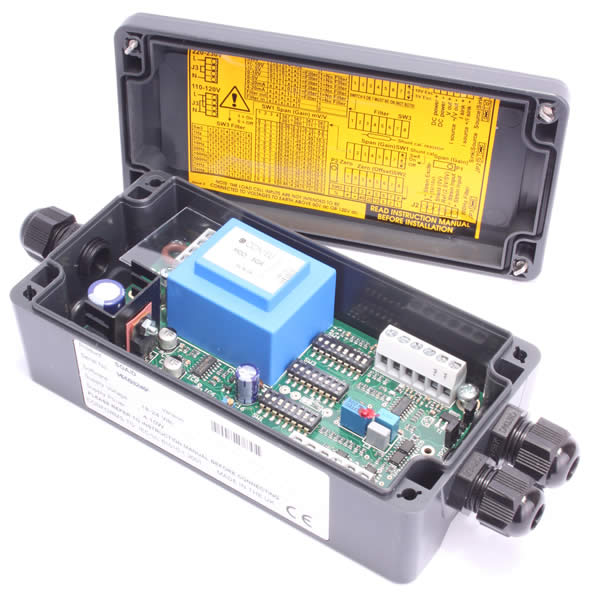

Applied Measurements SGA load cell amplifier / load cell signal conditioner is designed to provide a high stability, high speed, conditioned analogue output from up to four 350Ω strain gauge bridges connected in parallel.

The SGA load cell signal conditioner is capable of working with very low-level input signals right down to 0.06mV/V and amplifying them into a stable, high-level industry standard process signal such as 0-10Vdc or 4-20mA.

The high-speed load cell signal conditioner is housed in a rugged ABS enclosure rated to IP67 making it suitable for use in a wide range of industrial locations.

Other features of the load cell amplifier include straightforward configuration using non-interactive zero & span controls and variable low-pass filter to allow fine tuning for any application.

There are two versions of the load cell amplifier available: the SGA-A model which requires a 110 or 240Vac supply, and the SGA-D which operates from an 18-24Vdc supply.

The SGA load cell amplifier can be supplied fully-wired and calibrated with any strain gauge transducer from our wide range listed in the associated products section below.

Technical Specifications

| Parameter | Min | Typical | Max | Units |

|---|---|---|---|---|

| Power supply (SGA/A) 50 - 60Hz | 99/198 | 110/230 | 126/253 | Vac |

| Power supply DC (SGA/A and SGA/D) | 18 | 24 | Vdc (Note: 1) | |

| Power supply IS12/24 - Isolated (optional) | 9 | 36 | Vdc | |

| Power supply current DC :- (depends on loading) | 50 | 90 | 200 | mA |

| Bridge excitation (10V) 350R Strain Gauge | 9.75 | 10 | 10.25 | Vdc |

| Bridge excitation (5V) 350R Strain Gauge | 4.85 | 5 | 5.15 | Vdc |

| Bridge resistance | 85 | Ohms | ||

| Bridge sensitivity (Switchable) | 0.06 | 30 | mV/V | |

| Gain adjustment (Pot - fine adj.) | 0.06 | 1.0 | mV/V (Note: 2) | |

| Offset adjustment (Pot - fine adj.) | -1.25 | +1.25 | %FR (FR=Full Range) | |

| Offset adjustment (Switchable - coarse adj) | ±1.25 | ±80 | %FR | |

| Output load (Voltage output) | 2 | mA | ||

| Output load (Current output) | 0 | 500 | Ohms | |

| Bandwidth (No filter and > 2mV/V) - 3dB point | DC | 6 | kHz | |

| Filter cut-off (Switchable ranges) - 3dB point | 1 | 5000 | Hz | |

| Zero temperature coefficient (@ 2.5mV/V) | 0.002 | 0.009 | %FR/ ºC at 2.5mV/V FR | |

| Span temperature coefficient | 0.007 | 0.01 | %FR/ ºC | |

| Linearity | 0.03 | %FR | ||

| Gain stability -1st 1000 Hours | 0.2 | %FR | ||

| Gain stability - 2nd 1000 Hours | 0.1 | %FR | ||

| 90 day Offset stability | 3.3 | uV | ||

| Output load stability gain (0 - 100%) | 0.01 | %FR | ||

| Output load stability offset (0 - 100%) | 0.01 | %FR | ||

| Power supply rejection gain (0 - 100%) | 0.01 | %FR | ||

| Power supply rejection offset (0 - 100%) | 0.01 | %FR | ||

| Operating temperature range | -10 | 50 | ºC | |

| Storage temperature range | -20 | 70 | ºC | |

| Humidity | 95 | % | ||

| Note 1: 18V max at full load. | ||||

| Note 2: Depends on sensitivity settings | ||||

| Output Options Set by On-Board Switch | ±10V, ±5V, 0-10V, 0-5V, 0-20mA, 4-20mA | |||

| Connections | Field screw terminals - 2.5mm² rising clamp | |||

| Enclosure | ABS case 164 x 84 x 55 sealed to IP65 fitted with 3 off cable glands | |||

| Controls | Gain pot, Offset pot, Coarse gain switches, Coarse offset switches, Filter cut-off switches, Output mode switch | |||

| CE Environmental Approvals | European EMC Directive 2004/108/EC, Low Voltage directive 2006/95/EC | |||

Product Dimensions

Ordering Codes & Options

| Core Product | Supply Voltage | Example Result |

|---|---|---|

| SGA | 99-120/198-253Vac (in ABS case) | SGA/A |

| SGA | 18-28Vdc (in ABS case) | SGA/D |

| SGA | 18-28Vdc (PCB only) | SGAPCB/D |

| D4 | DIN Rail Mounts for SGA Case | D4 |

| IS1224 | Isolated 9-32Vdc PSU for SGA/D | IS1224 |

| SGABCM | ¼ & ½ Bridge Completion Module | SGABCM |

Case Studies

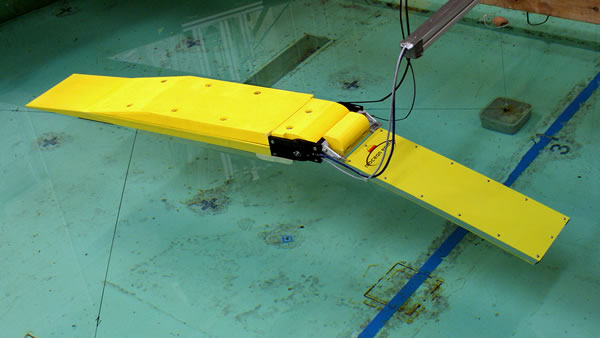

Incredible Miniature Reaction Torque Sensor Helps Create Ocean Energy

The YDNS miniature reaction torque sensor's compact size and in-line direct drive measurement capability meant it could easily be housed within the waterproof enclosure of the 1/50th scale wave energy converter.

Applied Measurements’ Displacement Transducers Make Tracks Through Turkey

Applied Measurements were asked to design a bespoke bridge monitoring system for Turkey’s new rail tunnel – The Marmaray Project. We created a bespoke bridge monitoring system using 3 off 50mm AML/SGD displacement transducers, forming a triaxial measurement of each joint. The AML/SGD series of displacement transducers utilise strain gauge technology to convert the linear movement of the joints within the tunnel into an analogue electrical signal. The AML/SGD series of displacement transducers were chosen for their excellent accuracy (0.1%), coupled with their high resolution and long-term stability, making them a perfect transducer for The Marmaray Project.

Why Applied Measurements?

- Suppliers of top quality strain gauge sensors and transducers to every corner of industry - UK and worldwide

- Over 100 years of expert transducer knowledge

- Our high quality products all come with a 3 year warranty

Popular Products

Platform Load Cell | Single Point Load Cell | 0-250g to 0-40kg | OBUG

0-250g to 0-40kgFrom £128Universal Load Cell | Universal S-Beam Force Sensor | DBBSM

0-1kg up to 0-30,000kgFrom £254Buy OnlineHandheld Load Cell Indicator | Digital Display | TR150

From £308Buy OnlineStrain Gauge Displacement Sensor | Linear Position Sensor | AML/SGD

0-5mm to 0-100mmFrom £425Buy Online