This product has been discontinued.

Please use our Industrial Pressure Sensor | Pa600 instead.

At a Glance

- Ranges: 0-50mbar up to 0-700bar

- Outputs: mV / Volts / mA

- Environmental Protection: IP65

- Accuracy: <±0.25%/FS (0.1% option)

- Optional IP66 or IP68 Sealing

- Ideal for Both General Purpose and Industrial Applications

- Marine and Offshore Submersible Versions Available

- Protected from Low-Pressure Water Jets as Standard

- Customised Versions Available to Suit Your Application

- Fast and Simple Setup with Custom Process Connections

Description

The Pi600 industrial pressure sensor is designed for the measurement of gas and liquid pressure across a wide range of general-purpose and industrial applications including hydraulics, medical, research and development, meteorology and food processing.

The industrial pressure sensor offers excellent media compatibility as standard with its stainless steel case, ceramic sensing element and Viton ‘O’ ring seal. Alternative case and ‘O’ ring materials available for applications where very aggressive media is present.

The Pi600 industrial pressure sensor series offers a wide choice of electrical outputs from it’s ASIC-based amplifier circuit, these include 4-20mA, 0-5Vdc & 0-10Vdc, 1-6Vdc and 10mV/V, as well as a ratiometric 0.5-4.5Vdc signal that requires a 5Vdc supply to suit most data loggers.

A G¼” male process connection is offered as standard along with a choice of alternatives including G½” male, G¼” female, ¼” NPT male and ½” NPT male. Custom process connections can also be offered if required.

We are also able to customise the Pi600 industrial pressure sensor to suit your exact requirements if necessary, whilst ensuring a minimal effect on price and availability.

Technical Specifications

| Input Pressure Range | ||||||

|---|---|---|---|---|---|---|

| Nominal Pressure Range | mbar (gauge, absolute or sealed gauge | 50 | 100 | 160 | 250 | 500 |

| Compound Ranges | bar | - | - | - | - | - |

| Permissible Overpressure | bar | 2 | 2 | 2 | 2 | 5 |

| *<±0.1% / FS (BFSL) accuracy not possible in this range | ||||||

| Output Signal & Supply Voltage | Wiring System | Output | Supply Voltage | Input Current | Input Resistance | Output Resistance |

|---|---|---|---|---|---|---|

| Pi642 | 2 – wire | 4 – 20 mA | 9 – 32 Vdc | n/a | <500 | <500 |

| Pi605 | 3 - wire | 0 – 5V dc | 9 – 32 Vdc | <6 mA | <500 | <500 |

| Pi6010 | 3 - wire | 0 – 10V dc | 13 – 32 Vdc | <6 mA | <500 | <500 |

| Pi615 | 3 - wire | 1 – 5V dc | 9 – 32 Vdc | <6 mA | <500 | <500 |

| Pi6110 | 3 - wire | 1 – 10V dc | 13 – 32 Vdc | <6 mA | <500 | <500 |

| Pi616 | 3 - wire | 1 – 6V dc | 9 – 32 Vdc | <6 mA | <500 | <500 |

| Pi606 | 3 - wire | 0 – 6V dc | 9 – 32 Vdc | <6 mA | <500 | <500 |

| Pi645 | 3 - wire | 0.5 to 4.5V dc | 5 Vdc | <6 mA | <500 | <500 |

| Pi602 | 4 – wire | Passive mV/V (un-rationalised) | 2 – 30 Vdc | <3 mA typ. | <11000 | <11000 |

| Pi607 | 4 – wire | 2mV/V (rationalised) | 2 – 30 Vdc | <3 mA typ. | <11000 | <11000 |

| Pi610 | 4 – wire | 10mV/V (amplified) | 3 – 12 Vdc | <3 mA typ. | <11000 | <200 |

| Performance | ||

|---|---|---|

| Accuracy (non-linearity, hysteresis, repeatability) | % Full Scale Output | <±0.25 (BFSL) |

| <±0.1 (BFSL) optional | ||

| Zero Balance | ±% of Rated Output | <1.0 |

| Setting Errors (offsets) | 2-wire, 3-wire | Zero & Full Scale, <±0.5% / FS |

| 4-wire rationalised | Zero <0.2mV/V, span ±1% | |

| 4-wire un-rationalised | Zero<0.1mV/V, Span ±30% | |

| Permissible Load | 2-wire | Rmax = [(VS – VS min) / 0.02] Ω |

| 3-wire | Rmin = 10 k Ω | |

| 4-wire | Rmin = 11 k Ω | |

| Influence Effects | Supply Effects | mV/V & 0.5 to 4.5V – Ratiometric, Other Voltage Outputs - <0.005 % FS / 1V |

| Load Effect | 4-20mA = <0.05 % FSO / kΩ | |

| Response Time (10% - 90%) | ms | ≤1 (mV/V versions) ≤10 (amplified versions) |

| Warm-Up Time (amplified versions only) | ms | 2 typ. |

| Media Temperature | ˚C | -20 to +135 / -40 to +125 below 1bar (150 with optional integrated cooling element) |

| Ambient Temperature | ˚C | -20 to +80 |

| Storage Temperature | ˚C | -40 to +125 |

| Compensated Temperature Range | ˚C | +20 to +80 |

| Thermal Zero Shift (TZS) | % / FS / ˚C | <±0.04 (standard) |

| <±0.02 (option) | ||

| <±0.01 (option) | ||

| Thermal Span Shift (TSS) | % output / ˚C | <-0.015 |

| Reverse Polarity Protection | No damage but also no function | |

| Electromagnetic Compatibility | CE Compliant | |

| Insulation Resistance | Megohms Ω at 50V dc | >500 |

| Shock | 100 g / 11 ms | |

| Vibration | 10 g RMS (20 ... 2000 Hz) | |

| Housing & process connection | 303 Stainless Steel | |

| 316L Stainless Steel (optional) | ||

| High Grade DUPLEX Stainless Steel UNS S31803 (optional) | ||

| ‘O’ ring seals | Viton | |

| NBR/Nitrile (optional) | ||

| EPDM (optional) | ||

| Chemraz (optional) | ||

| Diaphragm | Ceramic Al2O3 96 % (316L Stainless Steel below 1 bar) | |

| Media wetted parts | Housing and process connection, ‘O’ ring seal, diaphragm | |

| Weight | grams | 100 nominal |

| Installation position | Any | |

| Operational life | pressure cycles | > 100 x 106 |

| Environmental Protection | IP54, IP65, IP67 or IP68 | |

| See dimension drawings below for details. |

Product Dimensions

Dimensions are in mm

Wiring Details

| Small Plug & Socket (Code A) | Large Plug & Socket (Code B) | IP65 Cable (Code C) | AMP 6-pin Bayonet (Code D) | IP68 Vented Cable Code E) | Binder 6-pin Connector (Code F) | M12 x 1, 4-pin Connector (Code G) | ||

|---|---|---|---|---|---|---|---|---|

| 2 - wire | +ve Supply | Pin 1 | Pin 1 | Red | Pin 1 | Red | Pin 1 | Pin 1 |

| -ve Supply | Pin 2 | Pin 2 | Blue | Pin 2 | Blue | Pin 2 | Pin 2 | |

| Ground | Earth Pin | Earth Pin | Green | Earth Pin | White | Pin 3 | Pin 3 | |

| 3 - wire | +ve Supply | Pin 1 | Pin 1 | Red | Pin 1 | Red | Pin 1 | Pin 1 |

| -ve Supply | Pin 2 | Pin 2 | Blue | Pin 2 | Blue | Pin 2 | Pin 2 | |

| +ve Output | Pin 3 | Pin 3 | Green | Pin 3 | White | Pin 3 | Pin 3 | |

| Ground | Earth Pin | Earth Pin | Yellow | Earth Pin | Yellow | Pin 4 | Pin 4 | |

| 4 - wire | +ve Supply | Pin 1 | Pin 1 | Red | Pin 1 | Red | Pin 1 | Pin 1 |

| -ve Supply | Pin 2 | Pin 2 | Blue | Pin 2 | Blue | Pin 2 | Pin 2 | |

| +ve Output | Pin 3 | Pin 3 | Green | Pin 3 | White | Pin 3 | Pin 3 | |

| -ve Output | Earth Pin | Earth Pin | Yellow | Pin 4 | Yellow | Pin 4 | Pin 4 |

Case Studies

5 Reasons to Use Our Pressure Sensors in Your Diesel Injector Tester

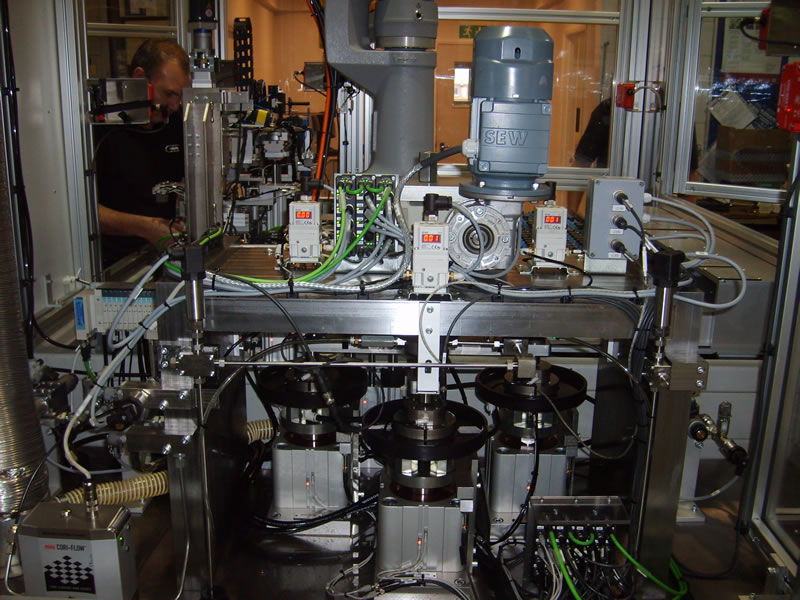

Curtis Assemble & Test Ltd, a designer and manufacturer of high-performance automotive test machines, use our pi600 industrial pressure sensors in their diesel injector valve pressure tester. “We choose to use Applied Measurements pressure transducers on our machines due to the reliability and competitive pricing. For us they are a fit and forget part,” explains Mark Hobday, Technical Development Engineer, Curtis Assemble & Test Ltd.

Pressure Transducer Delivers Water Level Monitoring in Emergency Tank Shower

Applied Measurements provided spill control and containment manufacturer Empteezy with a Pi600 series pressure transducer. The Pi600 series pressure transducer was connected and calibrated to the digital readout scale on the front of the shower giving an accurate reading of the litres of water remaining in the tank.

Why Applied Measurements?

- Suppliers of top quality strain gauge sensors and transducers to every corner of industry - UK and worldwide

- Over 100 years of expert transducer knowledge

- Our high quality products all come with a 3 year warranty

Popular Products

Platform Load Cell | Single Point Load Cell | 0-250g to 0-40kg | OBUG

0-250g to 0-40kgFrom £128Universal Load Cell | Universal S-Beam Force Sensor | DBBSM

0-1kg up to 0-30,000kgFrom £254Buy OnlineHandheld Load Cell Indicator | Digital Display | TR150

From £308Buy OnlineStrain Gauge Displacement Sensor | Linear Position Sensor | AML/SGD

0-5mm to 0-100mmFrom £425Buy Online