At a Glance

- Capacities: 0-50N up to 0-50kN

- Output: 0.75mV/V to 2mV/V

- Fully Submersible: IP68 to 10m

- Accuracy: <±0.15%/RC (0.05% typical)

- Optional Integral Amplifier

- Ideal for any Freshwater Application

- Fully Submersible Long-Term Immersion Protected

- Underwater Protection Guaranteed Thanks to ‘O’ Ring Sealing

- Greater Underwater Depth Ratings Available for Deep Sea Applications

- Special Versions Alternative Construction Materials for Seawater and other Corrosive or Aggressive Media.

Description

Applied Measurements high accuracy DDEN in-line submersible load cell can be used in both tension and compression and is specially designed for applications where load or force needs to be measured underwater, or in areas subject to high humidity or the risk of flooding.

The submersible in-line load cell is sealed using ‘O’ rings to provide integrity at depths up to 10 metres as standard, with greater depths possible if the appropriate modifications are made to the design. Applied Measurements standard in-line waterproof load cell model DDEN, is currently being used in various applications including wave tank measurement systems and mooring buoy cable tension monitoring.

Applied Measurements DDENA in-line submersible load cell is fitted with an ICA Series Load Cell Amplifier to provide a high-level analogue output, commonly 0-5Vdc, 0-10Vdc, ±10Vdc or 4-20mA, which is suitable for use with most data acquisition and control systems. An RS485 digital output is also possible by fitting the DCell Load Cell Digitiser in place of the ICA.

Customised versions of our DDEN submersible load cell can be designed to meet your specific requirements. Plus, instrumentation and rod ends are available to buy in our online shop, including calibration options to make a complete system.

Technical Specifications

| Rated Capacity (RC) | N | 0-50, 0-100, 0-250, 0-500, 0-1000, 0-2000, 0-5000, 0-10,000, 0-20,000, 0-50,000 |

|---|---|---|

| Operating Modes | Tension/Compression / Tension & Compression | |

| Sensitivity (RO) | mV/V (nominal) | 50N = 0.5 / 100N=1.0 / 250N = 0.75 / 500N = 1.5 / 1000N up = 2.0 |

| Zero Balance/Offset | ±%/Rated Output | <1.0 |

| Output Symmetry (tension vs. compression) | ±%/Rated Output | <0.25 typical |

| Non-Linearity | ±%/Rated Output (BFSL) | <0.15 (0.05 typical) |

| Hysteresis | %/Rated Output | <0.15 (0.05 typical) |

| Repeatability | ±%/Rated Output | <0.1 |

| Temperature Effect on Zero | ±%/Rated Output/ ˚C | <0.005 |

| Temperature Effect on Sensitivity | ±%/Applied Load/ ˚C | <0.005 |

| Input Resistance | Ohms | 700 |

| Output Resistance | Ohms | 700 |

| Insulation Resistance | Megohms | >5000 @ 50Vdc |

| Excitation Voltage | Volts AC or DC | 10 recommended (2-15 acceptable) - Note mV/V only, see page 5 for details of conditioned output versions. |

| Operating Temperature Range | ˚C | -20 to +80 |

| Compensated Temperature Range | ˚C | 0 to +70 |

| Storage Temperature Range | ˚C | -20 to +80 |

| Safe Overload | % of Rated Capacity | 150 |

| Ultimate Overload | % of Rated Capacity | 200 |

| Deflection @ Rated Capacity | mm | 50N=0.08; 100N=0.12; 250N=0.09; 500N=0.06; 1000N=0.04; 2000N=0.03; 5000N=0.02; 10,000N=0.015; 20,000N=0.01; 50,000N=0.03 |

| Fundamental Resonant Frequency* | kHz | 50N=1.7; 100N=1.3; 250N=0.72; 500N=1.18; 1000N=2; 2000N=3.1; 5000N=6.1; 10,000N=9.9; 20,000N=18.2; 50,000N=13.3 |

| IP Rating (Environmental Protection) | IP68 to 10m depth (please consult sales for greater depths) | |

| Weight (excluding cable) | kg | 50N to 20kN: 0.3kg / 50kN: 0.45kg, |

| Fatigue Life | 108 cycles typical (109 cycles on fatigue-rated version) | |

| Cable Length (as standard) | metres | 2 |

| Cable Type | 4-core screened submersible, PUR (weight: 82g/m) sheath, Ø7.5 | |

| Construction Materials / Wetted Parts | 17-4PH Stainless Steel, 303 Stainless Steel, PUR, NBR, TPE, Silicone | |

| Resolution | 1 part in 250,000 (with appropriate instrumentation) | |

| Pressure Effect on Output | 9N/mH²O nominal | |

| *The resonant frequency is calculated with the body of the load cell attached to a large plate, ensuring that only the sensing element oscillates: This is vital to achieve the highest natural frequency and subsequent frequency response. | ||

Product Dimensions

All dimensions are in mm

Model | Capacity | A | B | C | ØD | E |

|---|---|---|---|---|---|---|

DDEN | 0-50N up to 0-20kN | 67 | 15 | 35 | 44 | M12x1.75 |

DDEN | 0-50kN | 71 | 18 | 35 | 44 | M16x2.0 |

DDENA | 0-50N up to 0-20kN | 67 | 15 | 35 | 44 | M12x1.75 |

DDENA | 0-50kN | 71 | 17 | 37 | 50 | M16x2.0 |

Wiring Details

| Wire | mV/V Output | 3-Wire Voltage or Current Otput | 4-Wire Voltage Output | 2-Wire Current | RS485 Digital |

|---|---|---|---|---|---|

| Red | +ve excitation | +ve supply | +ve supply | +ve supply | +5.4 to +18Vdc supply |

| Blue | -ve excitation | 0V common | -ve supply | -ve supply / signal | -ve supply |

| White | +ve signal (tension) * | +ve signal | +ve signal | N/C | RS485 (B) Data -ve |

| Yellow | -ve signal | N/C | -ve signal | N/C | RS485 (A) Data +ve |

| Screen | To ground - not connected to load cell body | ||||

| * +ve signal in tension is standard, +ve signal in compression can also be offered. | |||||

Ordering Codes & Options

| Core Product | Capacity (inc Engineering Units) | Cable Length (m) | Specials Code | Example Result |

|---|---|---|---|---|

| DDEN | 50N | 002 | 000 | DDEN-50N-002-000 |

| DDEN | 100N | 002 | 000 | DDEN-100N-002-000 |

| DDEN | 250N | 002 | 000 | DDEN-250N-002-000 |

| DDEN | 500N | 002 | 000 | DDEN-500N-002-000 |

| DDEN | 1000N | 002 | 000 | DDEN-1000N-002-000 |

| DDEN | 2000N | 002 | 000 | DDEN-2000N-002-000 |

| DDEN | 5000N | 002 | 000 | DDEN-5000N-002-000 |

| DDEN | 10kN | 002 | 000 | DDEN-10kN-002-000 |

| DDEN | 20kN | 002 | 000 | DDEN-20kN-002-000 |

| DDEN | 50kN | 002 | 000 | DDEN-50kN-002-000 |

Mounting And Installation Accessories

Rod End Bearings for Tension Use

Designed to align forces through the principle axis of the load cell thus reducing the effects of extraneous forces, hence offering improved performance from the cell.

Rod End Bearings are used where tensile forces are being applied.

Maintenance-free rod ends are a complete units made up of a housing with both an integral shank (with an internal or external thread) and a maintenance-free spherical plain bearing, located within the housing.

Key Features:

- Supports radial loads in a tensile or compressive direction.

- Suitable for unilateral loads – can support alternating loads and alternating loads in combination with bearing GE..UK-2RS, consult sales.

- Stainless Steel for corrosion resistance.

- Are maintenance-free.

- Fitted with radial spherical plain bearings.

- PTFE composite sliding contact surfaces.

- Enables compact adjacent construction thanks to its thin-walled design of the eye housing.

All dimensions are in mm

| LOAD CELL | ORDERING CODES | Size (D) | B | M | A | F | L | K | J | O | SW | G | GL | Static load C0 kN | Dynamic load C kN | Limiting Speed rev/min | Weight g |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DDEN + DDENA-50N to 20kN | GIRSW-12RR-316 | 12 | 16 | 12 | 32 | 50 | 66 | 22 | 17.5 | 15.4 | 19 | M12 | 22 | 34.5 | 32 | 300 | 115 |

| DDEN-50kN | GIRSW-16RR-316 | 16 | 21 | 15 | 42 | 64 | 85 | 27 | 22 | 19.3 | 22 | M16 | 28 | 60.5 | 52.5 | 230 | 230 |

Downloads

CAD Model Files

Our 3D models are provided in STEP format and can be viewed using FreeCAD. Other formats can be provided on request.

The .zip file below contains a separate model for each product variant.

Case Studies

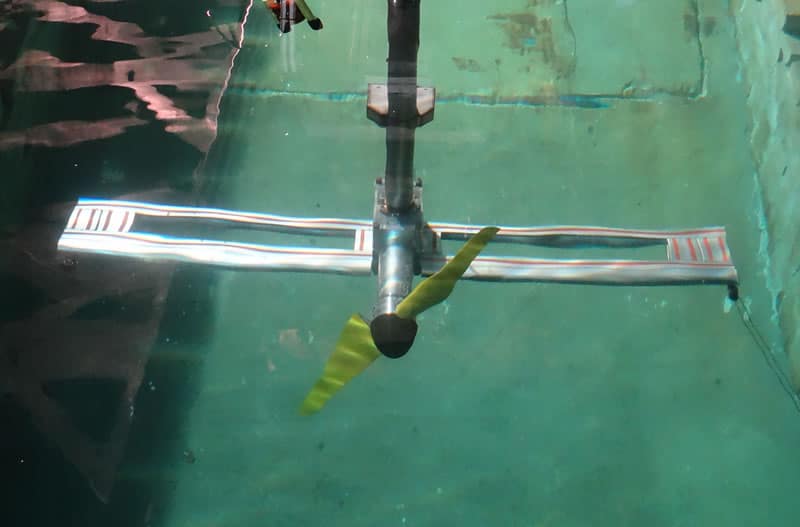

Submersible Load Cells Lower the Cost of Large Tidal Turbine Designs

This case study aims to significantly reduce the cost of large scale tidal turbine designs using our submersible load cells. The tidal turbine test rig was placed in a state-of-the-art test tank, where the team were able to increasing the size, flow rate and turbulence levels within the tank. Lowering the cost of rotor blade manufacture would make this renewable energy more economical to use and widely accessible, benefiting not only the UK renewable tidal energy markets but developing tidal energy countries too. Our submersible load cells measured both the torque and the thrust of the underwater tidal turbine design.

Why Applied Measurements?

- Suppliers of top quality strain gauge sensors and transducers to every corner of industry - UK and worldwide

- Over 100 years of expert transducer knowledge

- Our high quality products all come with a 3 year warranty

Popular Products

Platform Load Cell | Single Point Load Cell | 0-250g to 0-40kg | OBUG

0-250g to 0-40kgFrom £128Universal Load Cell | Universal S-Beam Force Sensor | DBBSM

0-1kg up to 0-30,000kgFrom £254Buy OnlineHandheld Load Cell Indicator | Digital Display | TR150

From £308Buy OnlineStrain Gauge Displacement Sensor | Linear Position Sensor | AML/SGD

0-5mm to 0-100mmFrom £425Buy Online