Applied Measurements needed to design and manufacture a pair of custom load pins for the university that could compensate for temperatures as low as -30degC. The load pin also had a built in ICA4S amplifier that could give a 4-20mA output for them to use to monitor the drilling forces.

Category: Custom Sensors

The Ultimate in Load Cell Design Flexibility from Applied Measurements

Here at Applied Measurements Ltd we are proud of our extensive range of standard load cells. These cover ranges less than 1000grams up to 1000 tonnes via our CCD range of column load cells and form a superb basis from which we design and build countless customised load cells. As a UK-based transducer manufacturer boasting over 50 years of design experience within our company we build all manner of load, force, torque, displacement and pressure sensors from scratch according to our customers’ design or modification requirements. Modification and new design requests are a daily occurrence so our sensor repertoire is constantly growing. Read on for a couple of recent examples of using a stock item and modifying it to our […]

Submersible Compression Load Cell Resists Freeze-Thaw Weathering

Applied Measurements have just designed and manufactured a special version of their compact CCG annular load cell (also known as a ‘ring load cell’ or ‘donut load cell’) for use in a particularly tough application where it is submerged 1 metre deep in potable water, subjected to a force of 160kN (~16 tonnes) and subjected to a repeated cycle of freezing and thawing. The load cell design utilises 17-4PH stainless steel for the sensing element and cover in conjunction with a stainless steel IP68 cable gland, submersible polyurethane cable and a double ‘O’ ring sealing system to ensure that the transducer’s integrity is maintained at all times. The submersible load cells achieved an accuracy of better than 0.5% of rated […]

LowStir Friction Stir Welding System

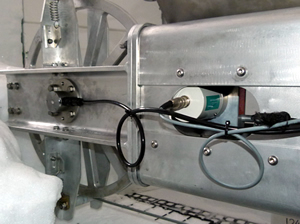

Friction stir welding is a welding process invented by TWI in 1991. The process involves a spinning tool, in contact with the material to be welded, with sufficient down force to create frictional heat in the material (about 80% of the material’s melting point). This causes the material to become soft, allowing the spinning tool to create the weld. Friction stir welding is now widely used in the aerospace, automotive, rail and ship building industries. Unlike other friction stir welders, the LowStir friction stir welding system includes a unit that attaches to most standard milling machines via an ISO taper, making it an affordable option to smaller enterprises. It is supplied with software to calibrate the system, monitor the welding […]

Custom Torque Sensors Now Available on Standard Lead Times

A UK manufacturer of torque sensors is offering custom designed static/reaction torque transducers on similar lead times to its standard units, with only a small premium on the standard list price. Applied Measurements Ltd, based in Aldermaston, is able to design and manufacture custom torque sensors to meet any customer requirement, including different flange diameters, unusual sizes of square drive, special sealed versions and shorter, more compact designs. According to Peter Lewis, Managing Director at Applied Measurements: “Many manufactured products require fatigue testing to ensure that they can operate for a guaranteed minimum period of time. An accelerated life test, for example, may be carried out on a drive shaft to determine the torque limits. The fatigue testing can sometimes […]

Custom Load, Pressure, Torque and Displacement Sensors for Machine Builders

By providing custom design services for its range of load cells, torque sensors, pressure transducers and displacement sensors, Applied Measurements Limited is helping machine builders and systems integrators to reduce lead times, cut costs and improve quality. “Despite the current economic downturn, we have grown our sales revenues by more than 30 per cent over the last three years,” says Peter Lewis, Managing Director at Applied Measurements Limited. “A major part of this growth is coming from our custom design service for our products, which include load cells, torque sensors, displacement sensors and pressure transducers. We are supplying one-off designs, pre-production prototypes, high volume specials, direct competitor equivalents, as well as modifying or strain gauging existing components.” According to Lewis, […]

High Volume, Low Cost OEM Strain Sensing Beam

The requirement was to design and manufacture a simple strain sensing beam to fit into a very confined space and meet a stringent budget. Following several months of design, development and creation the final product is manufactured from a high grade alloy steel requiring minimal additional machining. A single strain gauge containing a full Wheatstone bridge is bonded to the beam in a specific position to maximise the sensitivity and accuracy. During development a bespoke calibration system was also built to ensure that each strain sensing beam was accurately positioned and loaded for consistent quality. Following the successful acceptance trials and approval by our customer, the strain sensing beam has been put into full production, which is expected to exceed […]

Strain-Gauged Chain Link Measures Tension in Poultry Plant Conveyor System

The poultry plant was experiencing severe chain wear problems causing loss of production. It was suspected that this was due to excessive tension at certain points in the system. The challenge was to identify these areas, which could only be done effectively in a live running situation. Applied Measurements Ltd were supplied with a standard link from the chain, this was modified to enable strain gauges to be bonded to the structure, creating a strain-gauged chain link. The transformation of the link into a load cell was completed by terminating with a four core screened cable, environmental protective coatings and calibration. The strain-gauged chain link was then installed in the standard process chain and fitted with a portable data logger, […]