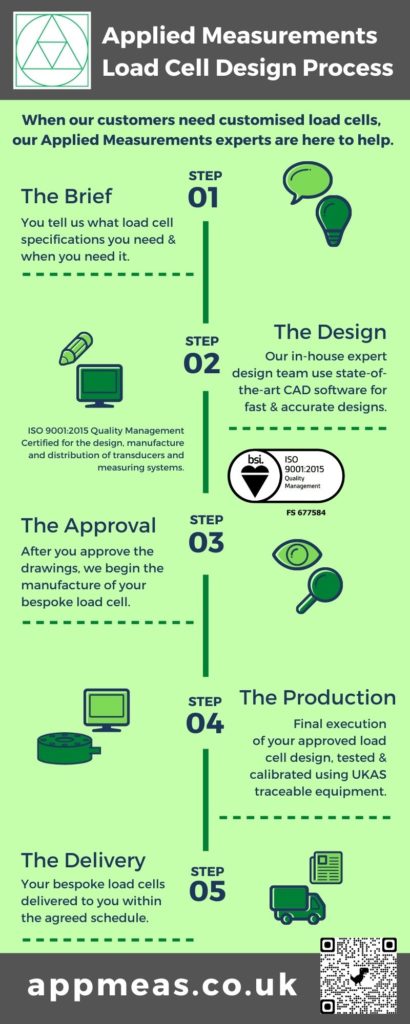

Do you need a unique load cell design for your application? How about an exact replacement for your existing one? See our 5 steps of our easy load cell design process.

Category: Custom Sensors

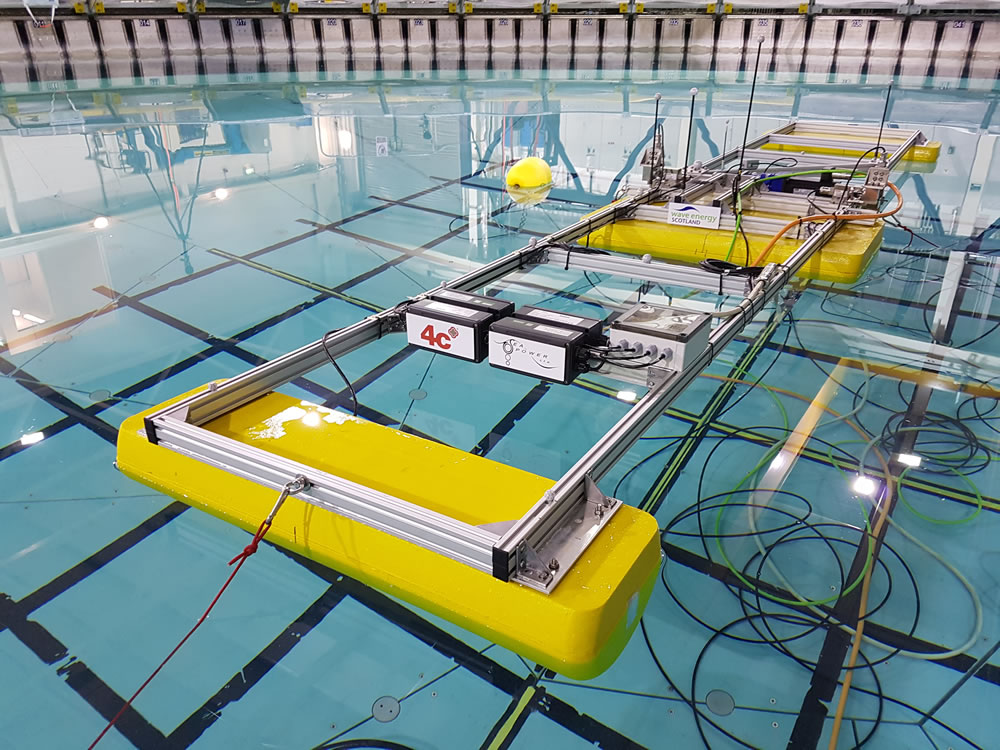

Real Life: Power Take-Off Torque Monitoring – Accurate, Fast and Simple!

Read the real life case study of power take-off torque monitoring on the Wave Energy Converter The SeaPower Platform. See how our complete torque measuring system enabled engineers to accurately monitor the torque applied by the Wave Energy Converter as it responded to waves in the test tank with accurate, fast and reliable results.

S-Beam Load Cells Promise Accurate Pigment Dispensing

We chose Applied Measurements’ DBBSM s-beam load cells as the pigment is £1000 per tonne so has to be extremely accurate” says Paul Akers, Works Manager at PD Edenhall Ltd. One of the largest independent concrete facing brick manufacturer in the UK, needed a way to accurately monitor the amount of pigment being dispensed into the weigh hopper throughout the manufacture of concrete facing bricks. The pigment amount needs to be precise as inaccurate amounts of pigment can lead to incorrect colour blends leading to a loss in sales and profit. Read how our accurate DBBSM s-beam load cells and intuitive4-L digital indicators were used in this construction industry application.

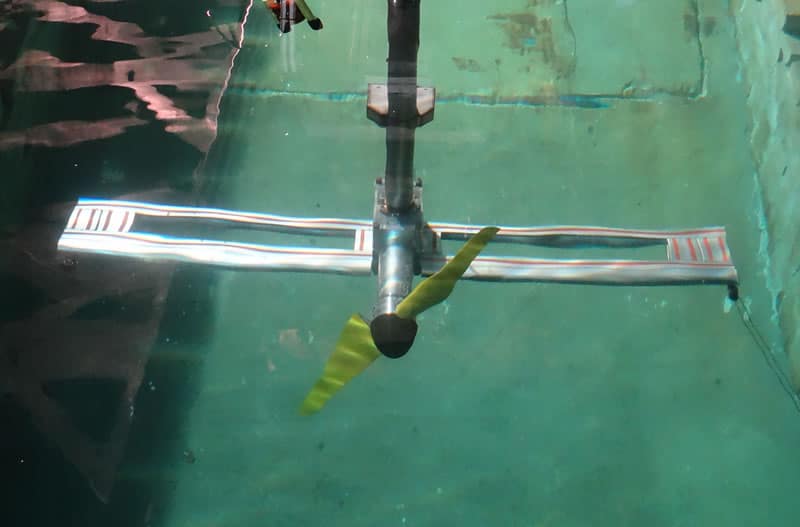

Submersible Load Cells Lower the Cost of Large Tidal Turbine Designs

This case study aims to significantly reduce the cost of large scale tidal turbine designs using our submersible load cells. The tidal turbine test rig was placed in a state-of-the-art test tank, where the team were able to increasing the size, flow rate and turbulence levels within the tank. Lowering the cost of rotor blade manufacture would make this renewable energy more economical to use and widely accessible, benefiting not only the UK renewable tidal energy markets but developing tidal energy countries too. Our submersible load cells measured both the torque and the thrust of the underwater tidal turbine design.

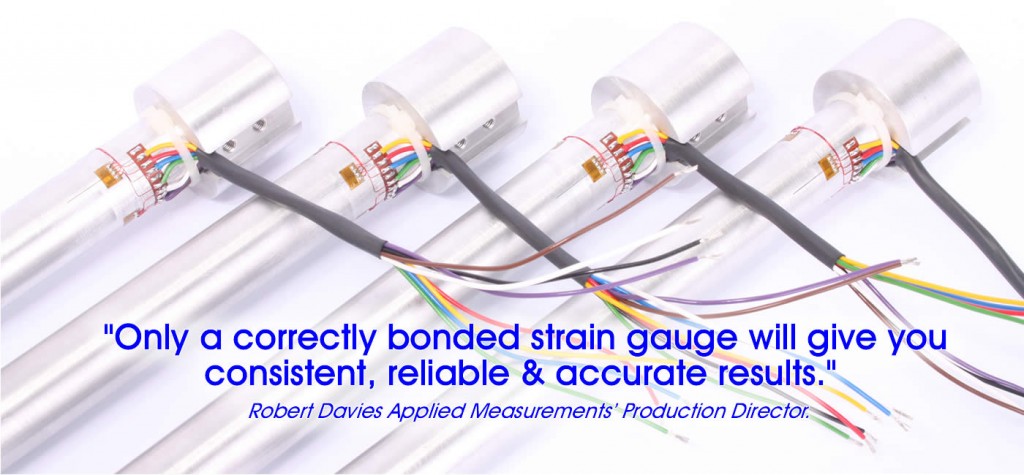

Try Our Strain Gauge Bonding Service from One-Offs to High Volume

Creating 1000 Times More Power with Submersible Load Measuring Pins

The measuring device needed to withstand permanent underwater submersion. “Our load measuring pin’s stainless steel construction and ability to be customised to IP68 submersion rating made this the ideal choice for use in Deep Green’s control system”, explains Ollie Morcom, Applied Measurements’ Sales Director.

STOP Our Flexible Approach Makes Load Cell Customisation Easy

We have over 20 years of designing and manufacturing custom built load cells to our customer’s specific requirements. From a single piece, a small batch or mass production, we really can cater for all. We provide an extensive load cell customisation service from minor modifications to the full design, development and manufacture of a completely bespoke product that’s unique to you and your business.

Our Shear Pin Load Cells and Draw Wire Sensors Deliver Flawless Results in Sub-Zero Temperatures

Applied Measurements were contacted by Victoria University of Wellington to provide reliable and accurate equipment that could operate in the sub-zero temperatures of the Antarctic. Using Applied Measurements’ two customised DBEP shear pin load cells, a WS12 draw wire sensor and four intuitive2 displays, the RICE team were able to successfully extract a 763m deep ice core from an ice cap on Roosevelt Island.