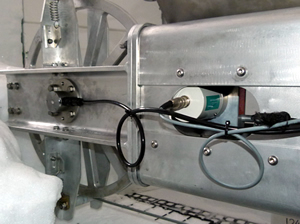

Applied Measurements were asked to design a bespoke bridge monitoring system for Turkey’s new rail tunnel – The Marmaray Project. We created a bespoke bridge monitoring system using 3 off 50mm AML/SGD displacement transducers, forming a triaxial measurement of each joint. The AML/SGD series of displacement transducers utilise strain gauge technology to convert the linear movement of the joints within the tunnel into an analogue electrical signal. The AML/SGD series of displacement transducers were chosen for their excellent accuracy (0.1%), coupled with their high resolution and long-term stability, making them a perfect transducer for The Marmaray Project.

Category: Displacement & Position

Load Pins and Position Sensors used for Antarctic Research

Applied Measurements needed to design and manufacture a pair of custom load pins for the university that could compensate for temperatures as low as -30degC. The load pin also had a built in ICA4S amplifier that could give a 4-20mA output for them to use to monitor the drilling forces.

Digital Multi-Channel Displacement Measurement System Replaces Dial Gauges

Applied Measurements were approached and asked to manufacture a 3-channel digital displacement measurement system to replace an ageing and difficult-to-monitor mechanical system based on dial gauges. The result was a neat, user-friendly, high accuracy system based on a strain gauge sensing principle and coupled with the very latest digital indication technology, all delivered within 2 weeks and backed up by an expert team of engineers. The basis for the system was the strain gauge-based AML/SGD displacement sensor that has been designed specifically to offer high resolution and accuracy in applications where the more conventional choice a LVDT or potentiometer type sensor does not offer sufficiently precise performance. In this instance a 10mm version of the AML/SGD was calibrated over a […]

New Range of Strain Gauge Based Displacement Transducers

Applied Measurements is pleased to announce the introduction of a new range of strain gauge based displacement transducers, the AML/SGD Series. It is now available with stroke lengths of 0-5mm, 0-10mm, 0-25mm and 0-50mm. The accuracy offered is +/-0.1% up to 25mm and +/-0.15% above 25mm, plus excellent long term and thermal stability. They require a stabilised dc voltage excitation anywhere between 2 and 10 volts and return a high level millivolt signal proportional to the position of the plunger. The AML/SGD Series are constructed using a rugged stainless steel tubular housing containing a spindle guide bearing and spring return mechanism. A light spring force ensures a minimal effect on the application and enables inverted operation when required. Precision construction […]

Miniature LVDT Displacement Sensor for OEM Applications

Applied Measurements’ new miniature LVDT displacement sensors have been designed to meet the needs of OEM applications making them suitable for use in load and pressure measurement, weighing equipment and closed loop control systems. The sensors use the well-proven LVDT technology with its advantages of no wearing parts together with reliable and accurate performance in a variety of operating conditions. The AML/M series of miniature LVDTs are available in measuring ranges from ±0.25mm up to ±75mm with a choice of mechanical attachments including core only, core and extension, plus sprung-loaded with ball end. The low mass of the core offers particular advantages in projects where minimal weight restrictions apply. All miniature LVDTs are calibrated to an accuracy of 0.5% of […]