In various applications it sometimes necessary to measure the pressure of fluids which are at temperatures either above or below the operating ranges of available sensors.

It is important to note that while some pressure sensors can tolerate higher media temperatures, the body of the sensor cannot, and must be mounted in a location as close to room temperature as possible at all times. Steps must be taken to protect sensors against high-temperature media.

Isolating the sensor

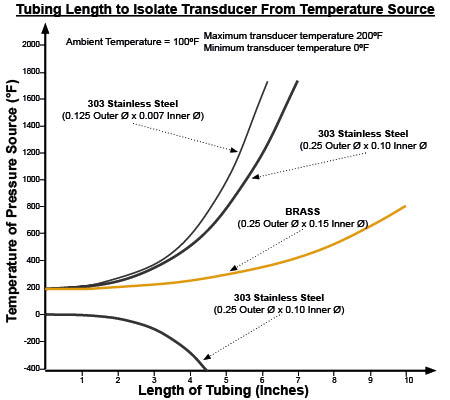

The expense of a special sensor can often be avoided if the pressure sensor is isolated from the pressure source by a short length of pipe or tubing. The curves below provide suggested tubing length, various sizes and materials, to limit temperatures between -100 and +1700°F (-240 to +920°C).

These curves are based on the following assumptions:

- The pressure vessel is insulated to limit radiant heat transfer to the sensor, and so the major source of thermal input is via the connecting tube.

- The pressure medium has a coefficient of thermal conductivity less than 0.4BTU/h/ft/ °F (this figure encompasses a wide range of liquids and gases).

- The heat transfer rate (convection) from the tubing to still air is 1.44/BTU/ft²/h/°F.

If there is any doubt a thermocouple on the sensor can be used to verify proper operating conditions.

Note

A 6in length of ¼in stainless steel tubing will effectively protect a sensor from a 1000°F (540°C) pressure source. Therefore a pressure sensor cable of operating at 200°F (93°C) can be used to measure the pressure of fluids at much higher temperatures.

Read more: Index to all of our Technical Notes on Pressure

Have a high temperature application you want to discuss? Let us call you…

Why Us?

- Suppliers of top quality strain gauge sensors and transducers to every corner of industry – UK and worldwide

- Over 100 years of expert transducer knowledge

- Our high quality products all come with a 3 year warranty