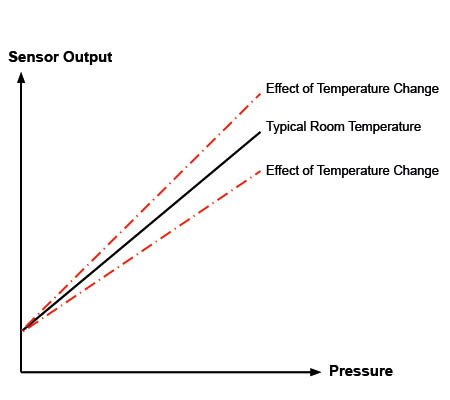

Span or sensitivity temperature shift represents the change in sensitivity due to changes in temperature. A change in temperature will cause a change in the slope of the sensor output curve.

The span shift due to temperature could typically be caused by the change in elasticity or spring constant of the gauges used in a sensor.

To minimise the span error with temperature, the most common used method for temperature compensation involves the addition of a temperature-sensitive resistor in series with the bridge work. The value of the resistor is determined from a temperature test run in which the change in span reading for the given temperature is found.

Normally the specified error is percentage of reading per degree Celsius including all error effects on linearity, hysteresis, repeatability and gradient sensitivity.

Watch out

Different manufacturers specify thermal effect on span in different ways: as error per degree Celsius, such as ±0.01%FS/°C; as a total temperature effect, in the form of ±1% of FS; or as an error band, such as ±1% over a 50°C temperature range. There are many more; some with reference to full scale, others that refer to reading. But in each case the specified error is only valid over the compensated temperature range.

Note that the temperature effect is only valid when the complete sensor housing is heated up. This is because some sensors have their temperature compensation at the rear of the housing.

A few manufacturers include both zero and span as a total value.

To understand all temperature effects please refer to the other engineering notes in this series.

Read more: Index to all of our Technical Notes on Pressure

Have a pressure application you want to discuss? Let us call you…

Why Us?

- Suppliers of top quality strain gauge sensors and transducers to every corner of industry – UK and worldwide

- Over 100 years of expert transducer knowledge

- Our high quality products all come with a 3 year warranty