True sensor interchangeability from unit to unit requires that the signal output of each sensor is preset to give the same output at zero pressure and the same span at full scale.

Sensor interchangeability means that the readings from one sensor should be within the set specifications as another identical sensor.

To manufacture one pressure sensor, test it and produce a specification sheet is easy. But if a manufacturer sets out to make hundreds or thousands of sensors it becomes increasingly difficult to guarantee that each sensor will perform within a certain accuracy. Even now we can run into problems, because all we have got to go on is a datasheet claiming that each sensor will perform within a given accuracy with regards to linearity, hysteresis and repeatability etc. But it does not tell us how the manufacturer has tested the unit, including zero and full scale output.

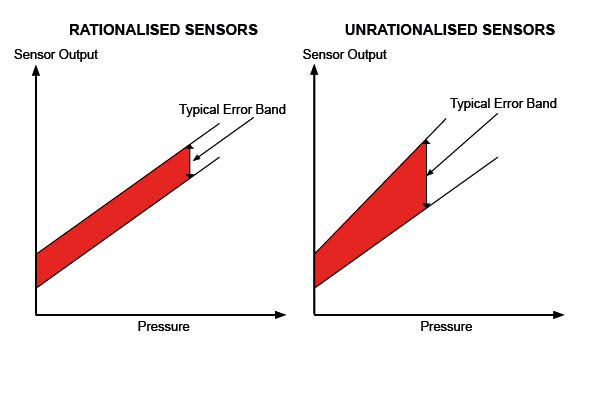

To install a sensor and achieve the same specification as given in the datasheet it is essential to have the information on how to set up and calibrate each sensor for. zero and full-scale output. Unfortunately, this is not the norm. Sensors do not always come with a complete set of specifications (more commonly called “with rationalised output”). You may have to ask for this option and find a dramatic increase in prices.

True interchangeability

True sensor interchangeability from unit to unit requires that the signal output of each sensor is preset to give the same output at zero pressure and the same span at full scale. The difference from unit to unit should be within a set specification. Otherwise the system builder will need to test every sensor and then calibrate each unit individually as part of the system.

You also have to consider the implications of replacing the sensor within a system: once you have dispatched a unit to your customer the cost of calibrating a sensor system in the field can be extremely high.

If a sensor is truly interchangeable, you should be able to simply swap sensors in the field and expect the system to remain within specifications.

Read more: Index to all of our Technical Notes on Pressure

Have a pressure application you want to discuss? Let us call you…

Why Us?

- Suppliers of top quality strain gauge sensors and transducers to every corner of industry – UK and worldwide

- Over 100 years of expert transducer knowledge

- Our high quality products all come with a 3 year warranty