Selecting a pressure sensor with the correct pressure range is not as straightforward as you might expect.

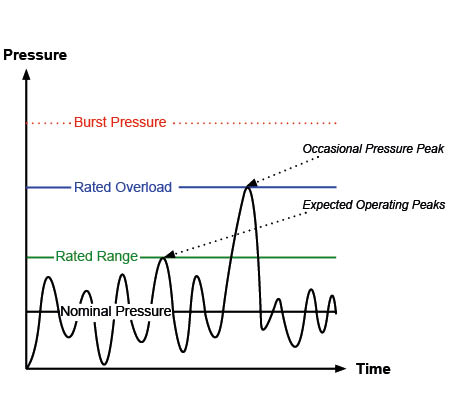

A sensor’s operating range is defined by three specifications:

- Rated (operating) range

- Overpressure limit

- Burst pressure

In a “real” application, these three pressure ratings are not always easy to define. The figure below shows all three levels superimposed on a curve of pressure against time for a sample application. The normal system pressure variations should all take place within the rated pressure range.

Overpressure

If you have overpressure waves, you need to choose a sensor that covers the maximum pressure in the application (ie use a device with a higher pressure range).

However, if you have pressure spikes then some form of protection is required. There are many such devices available that can be screwed onto the front port of the sensor (on the pressure port side) and which function very much like a a sponge.

Most overpressure spikes are created by suddenly stopping or starting a liquid flow. Common industrial sources include valves, solenoids, centrifugal pumps, regulators and the mounting positions of the sensors on the pipework.

There are many different designs of overpressure adapters on the market. Some work by restricting access to the diaphragm using a small hole to restrict pressure drop, others include piston and bladder types, accumulators, labyrinths etc. However, each of these will only stop spikes. They offer no protection against long-term overpressure.

Note

Fitting a pressure-protection “snubber” will affect the response time of the sensor. And while this will not normally cause any problems for the control system, it may not necessarily cure the problem. It is very much a “suck it and see” situation. In some applications it may be necessary to fit several snubbers.

Read more: Index to all of our Technical Notes on Pressure

Have a pressure application you want to discuss? Let us call you…

Why Us?

- Suppliers of top quality strain gauge sensors and transducers to every corner of industry – UK and worldwide

- Over 100 years of expert transducer knowledge

- Our high quality products all come with a 3 year warranty