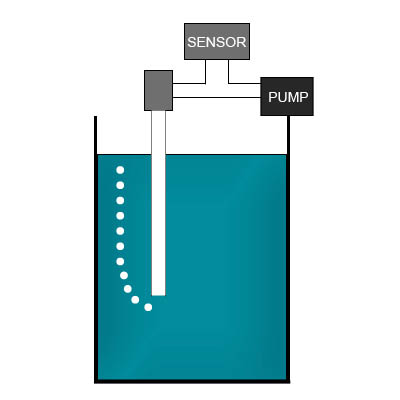

Liquid levels can be measured by using the bubble principle, by mounting a 1bar (15psig) pressure sensor on the discharge side of a high-reliability commercial aquarium air pump (as shown in the diagram below). The pressure required to bubble air through an immersed pipe is directly related to the liquid level.

Using a large pipe reduces the possibility of clogging and creates a system that is relatively self-cleaning. This method also safeguards the sensor as it is not immersed in the liquid.

Various “liquids” such as cream, chocolate, paint, sewage etc are held in agitated holding tanks. In such applications liquid levels are maintained between predetermined points by the sensor, which not only provides level information but can also be used to turn off the filling pump to the tank.

Pressure characteristics

The level sensor pressure changes from 2 to 12psig with random ripple resulting from surging.

Read more: Index to all of our Technical Notes on Pressure

Have a pressure application you want to discuss? Let us call you…

Why Us?

- Suppliers of top quality strain gauge sensors and transducers to every corner of industry – UK and worldwide

- Over 100 years of expert transducer knowledge

- Our high quality products all come with a 3 year warranty