What is a triaxial test?

A triaxial test is performed on a cylindrical core soil or rock sample to determine its shear strength.

The triaxial test attempts to replicate the in-situ stresses (stresses in the original place the soil sample was taken) on the core soil or rock sample.

Why is triaxial testing carried out?

Finding out the shear strength of soil and rock samples enables engineers to determine both the long-term and short-term effects of the core soil in large-scale engineering applications such as slope failure, earth dams, tunnels linings, subsoil structures, embankments and foundations.

How does a triaxial test work?

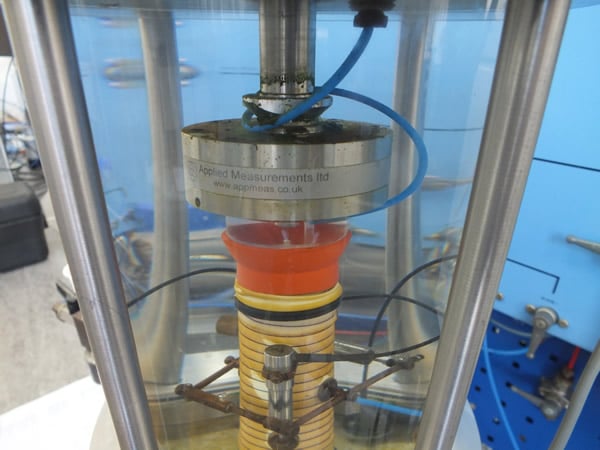

The cylindrical soil sample is vertically sealed within a thin rubber membrane and placed between two porous discs at the top and bottom end. The cylindrical soil sample is then positioned between a top loading plate and placed on a pedestal inside a triaxial pressure chamber.

The pressure chamber is filled with fluid which applies fluid pressure to the sides of the cylindrical soil sample. Vertical or axial stress is applied to the cylindrical sample by applying force to the moveable top-loading plate.

Typically, the soil sample has a 2:1 height to diameter ratio.

An LVDT displacement transducer can be used to measure the distance the top plate moves. Alternatively, the force needed to move the top plate can determine the distance the plate has moved.

The net volume of the fluid in the pressure chamber is monitored by the amount of water that moves out of the core sample’s pores.

A stalc3 submersible load cell installed above the top plate measures the axial force applied to the soil sample. The STALC3 load cell is fully submersible to IP68 rated and works with pressures up to 7000kPa or 70bar. The mV/V analogue readings can be sent to a variety of instrumentation for data logging and analysis.

Pore Pressure Measurement

Our Pa600 industrial pressure sensors can be connected to the pore water pressure line of the soil sample to measure the change in pore pressure.

During the saturation phase, in both the CU and CD test stages, all the voids within the sample are filled with water. The saturation process is performed slowly to increase the pressure and remove any water within the sample.

The Pa600 pore pressure sensor monitors the fluctuations in pressure, allowing the engineer to calculate the level of saturation in the sample.

There are 3 main types of triaxial tests

- Unconsolidated – undrained (UU)

- Consolidated – undrained (CU)

- Consolidated – drained (CD)

Unconsolidated – undrained (UU) triaxial test

The unconsolidated – undrained triaxial test is the fastest test, typically completed under 30 minutes. It is performed on cohesive soil samples to determine the undrained shear strength of the core sample.

It has no saturation or consolidation stage and is a short-term test to determine short-term engineering problems. It only has a shear stage.

In this triaxial test, the loads are applied quickly and the sample is not allowed to consolidate.

Consolidated – undrained (CU)

Both the consolidated – undrained (CU) and the consolidated – drained (CD) tests begin with a saturation stage, followed by a consolidation stage and ending with a shear stage.

The CU triaxial test is the most common. The soil sample is not allowed to drain and measures both the pore water pressure and the excess water pore pressure change of the soil sample during the shearing stage.

Pore pressure, as well as cell pressure and back pressure, can be monitored using our Pa600 pore pressure sensor.

This triaxial test can take weeks or months to perform and determines long-term engineering problems

Consolidated – drained (CD) longest test

The consolidated–drained (CD) tests begin with a saturation stage, followed by a consolidation stage, ending with a very slow shear stage.

The CD test is the longest triaxial test out of the three main types as the consolidated and shear stage must be carried out slowly. The pore pressure in the sample must not be allowed to build up and the test must allow the pore pressures to disperse.

The CD test determines long-term engineering problems.

If you like the article, please share it with others!

Stalc3 Submersible Load Cell for Triaxial Test Chambers

Our STALC3 submersible load cell is specifically designed to use in high-pressure triaxial chambers. They are guaranteed to work fully submersible in fluid pressures up to 7000kPa /70bar. They have an extremely high accuracy of less than ±0.05% of the rated capacity so are ideal for high accuracy laboratory applications. Thanks to their temperature compensation & high stability, they are ideal for long-term testing.

- Designed for High-Pressure Triaxial Test Chambers

- IP68 Fully Submersible

- Guaranteed for Water Pressures up to 7000kPa /70bar

- Ideal for Long-Term Testing

- Pressure Compensating System Ensures Optimum Performance Under High Pressure.

- For Use in Both Water and Oil

We have been providing the Imperial College London STALC3 submersible load cells to use in their triaxial chambers for over 15 years now! Can we help you too?

Why Us?

- Suppliers of top quality strain gauge sensors and transducers to every corner of industry – UK and worldwide

- Over 100 years of expert transducer knowledge

- Our high quality products all come with a 3 year warranty