Curtis Assemble & Test Ltd, a designer and manufacturer of high-performance automotive test machines, use our Pi600 industrial pressure sensors in their diesel injector valve pressure tester.

“We choose to use Applied Measurements pressure transducers on our machines due to the reliability and competitive pricing. For us they are a fit and forget part,” explains Mark Hobday, Technical Development Engineer, Curtis Assemble & Test Ltd.

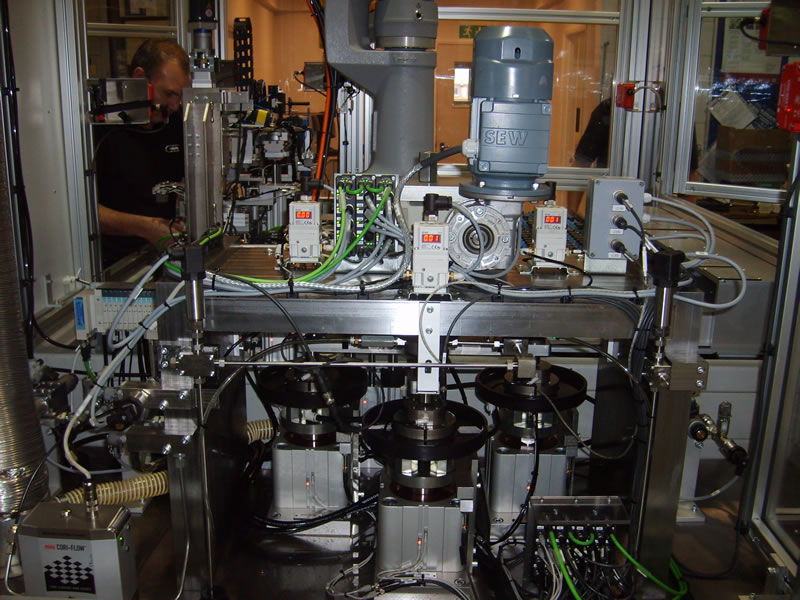

Three Pi600 industrial pressure transducers have been installed in a pressure test machine for testing diesel injector valves, see image above. They are used to check for seat integrity and RDO flow using three different pressure tests.

- The 1st and 2nd tests are up to 3000bar and measure for pressure decay.

- The 3rd test is up to 300 bar and the transducer is used to servo control the pressure.

That’s Curtis Assemble & Test’s reasons to use our pressure sensors.

Now, we give you our 5 reasons to use the Pi600 industrial pressure sensors for your diesel injector testing.

1) Excellent media compatibility – ideal for diesel test fluid applications

Thanks to its stainless steel case, the ceramic sensing element and the Viton ‘O’ ring seal, the Pi600 industrial pressure sensors lend themselves to use in a variety of gas and liquids. Plus, to use in more aggressive media, we can provide alternative case and ‘O’ ring materials to suit your application.

The industrial pressure sensors were ideal for this diesel injector tester as they needed to withstand diesel test fluid ISO 4113, the calibration fluid used for diesel injection equipment.

2) IP65 high environmental protection – optional IP66 or IP68 sealing

As standard, the industrial pressure sensors come with an IP65 protection rating, meaning they are dust-tight and splash-proof. Their protection rating can be further enhanced for more arduous applications. They can be protected from high-pressure water jets at IP66 rated and even protected from long-term immersion (IP68), at a pressure specified by you.

3) High accuracy <±0.25% of full scale (0.1% optional)

The industrial pressure sensors are high performance and highly accurate to less than ±0.25% of full scale. This makes them ideal for hydraulics, medical, research and development, meteorology and food processing applications. Plus, if you need higher accuracy, optional 0.1% accuracy is available for applications requiring a higher degree of measurement.

4) Wide range of outputs: mV / Volts / mA

Their ASIC-based amplifier circuit means the industrial pressure sensors can offer a wide choice of electrical outputs to suit your specific pressure application. The outputs include 4-20mA, 0-5Vdc & 0-10Vdc, 1-6Vdc and 10mV/V, as well as a ratiometric 0.5-4.5Vdc signal that requires a 5Vdc supply which suits most standard data loggers.

5) Customisation to suit your exact requirements

Still think the industrial pressure sensors might not be suitable for your application? Think again. These units can be customised to suit your specific requirements making them perfect for your application.

Custom options include:

- Electrical Output

- Electrical Connections

- Pressure Range: 0-50mbar up to 0-700bar

- Accuracy Options

- Zero Temperature Compensation

- Process Connections

- O-Ring Material

- Cable Lengths

Order your own industrial pressure sensor today

Email our technical team or call us on (+44) 0118 981 7339.