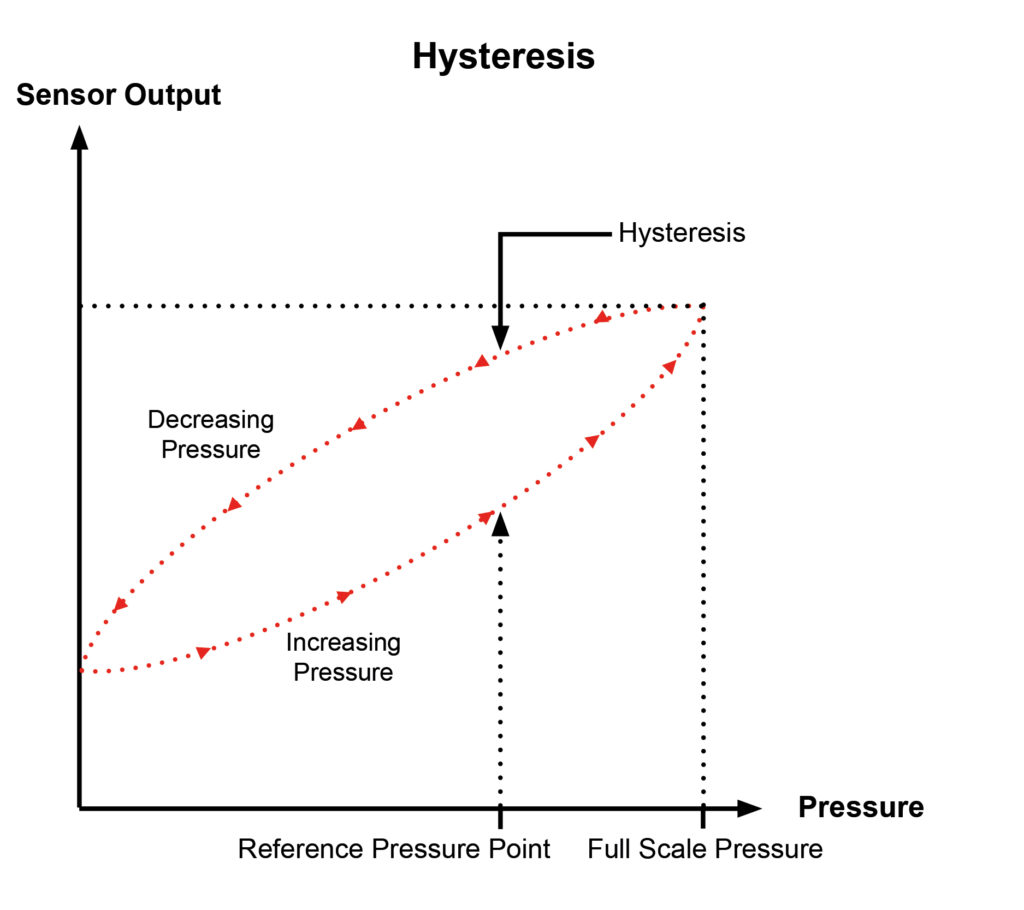

The hysteresis error of a pressure sensor is the maximum difference in output at any measurement value within the sensor’s specified range when approaching the point first with increasing and then with decreasing pressure.

The hysteresis error value is normally specified as a positive or negative percentage of the specified pressure range. If a sensor is only used over half of the specified range the hysteresis error is calculated from this value.

By using the maximum working pressure, the accuracy is, of course, better than specified by the manufacturer (for example the percentage of working pressure). Also, the hysteresis error is usually expressed as a combination of mechanical and temperature hysteresis.

Mechanical hysteresis

Mechanical hysteresis is the output deviation at a certain input pressure when that input is approached first by increasing and then by decreasing pressure.

Temperature hysteresis

Temperature hysteresis is the output deviation at a certain input pressure, before and after a temperature cycle.

Hysteresis errors are not always specified separately but combined in a total figure for linearity, hysteresis and repeatability.

If you like the article, please share it with others.

Read more: Index to all of our Technical Notes on Pressure

Interested in discussing your transducer’s hysteresis errors? Let us call you…

Why Us?

- Suppliers of top quality strain gauge sensors and transducers to every corner of industry – UK and worldwide

- Over 100 years of expert transducer knowledge

- Our high quality products all come with a 3 year warranty