At a Glance

- Capacities: 0-10Nm to 0-10kNm

- 1.5mV/V Output (nominal)

- Environmental Protection: IP65

- Accuracy: <±0.25%/Rated Capacity

- Custom Capacities to 50kNm+

- Designed for In-Line Static or Semi-Rotary Torque Measurement

- High Accuracy – Ideal for Calibration, Development and Testing Applications

- Integral Bayonet Lock Military Connector Ensures Simple & Easy Connection

- Fast Installation with Customised Shaft and Configuration Options

- Let us Customise the Design to Suit Your Exact Application

Description

The DTD-P parallel shaft reaction torque transducer / reaction torque transducer series have keyed parallel shaft connections for in-line direct drive measurements. Applications include the testing of electrical motors, hydraulic pumps, automotive transmissions, steering systems and aircraft actuators.

We are able to offer custom shaft sizes and configurations to suit your application if required. Request pricing from our technical sales team.

Technical Specifications

| Rated Capacity (RC) | Nm | 0-10, 0-20, 0-50, 0-100, 0-200, 0-250, 0-500, 0-1000, 0-2k, 0-5k, 0-10k |

|---|---|---|

| Operating Modes | Clockwise (CW)/Counter-Clockwise (CCW) / Clockwise (CW) & Counter-Clockwise (CCW) | |

| Sensitivity (RO) | mV/V | 1.5 nominal |

| Zero Balance/Offset | ±%/Rated Output | <1 |

| Output Symmetry (CW vs. CCW) | ±%/Rated Output | <0.25 typical |

| Non-Linearity | ±%/Rated Output (BFSL) | <0.1 |

| Hysteresis | ±%/Full Scale Output | <0.1 |

| Repeatability | ±%/Full Scale Output | <0.01 |

| Temperature Effect on Zero | ±Full Scale Output/ ˚C | <0.01 |

| Temperature Effect on Output | ±/Reading/ ˚C | <0.01 |

| Bridge Resistance | Ohms | 700 nominal |

| Insulation Resistance | Megaohms | >5000 @ 50Vdc |

| Excitation Voltage | Volts AC or DC | 10 recommended (2-15 acceptable) |

| Operating Temperature Range | ˚C | -20 to +80 |

| Compensated Temperature Range | ˚C | +20 to +70 |

| Storage Temperature Range | ˚C | -20 to +80 |

| Safe Overload | % of Rated Capacity | 150 |

| Ultimate Overload | % of Rated Capacity | 300 |

| IP Rating (Environmental Protection) | IP65 | |

| Weight | Speak to sales | |

| Fatigue Rating | 108 cycles typical (109 cycles on fatigue rated version) | |

| Cable Length (as standard) | metres | 3 |

| Cable Type | 4-core screened PUR, Ø4.6mm | |

| Construction | Stainless Steel | |

| Resolution | 1 part in 250,000 (with appropriate instrumentation) | |

Product Dimensions

| Capacity (Nm) | ØA h6 | B | C | D | E | ØF | G |

|---|---|---|---|---|---|---|---|

| 0-10, 0-20 | 12 | 25 | 23 | 100 | 50 | 38 | 5 |

| 0-50, 0-100 | 20 | 30 | 25 | 126 | 66 | 44 | 6 |

| 0-200, 0-250 | 30 | 45 | 40 | 162 | 72 | 60 | 8 |

| 0-500 | 30 | 45 | 40 | 162 | 72 | 60 | 10 |

| 0-1000 | 50 | 75 | 45 | 232 | 82 | 74 | 16 |

| 0-2500, 0-5000 | 75 | 115 | 110 | 320 | 90 | 85 | 22 |

| 0-10,000 | 100 | 150 | 145 | 430 | 130 | 110 | 25 |

All dimensions are in mm.

Wiring Details

| Wire | Designation |

|---|---|

| Red | +ve excitation |

| Blue | -ve excitation |

| Green | +ve signal (clockwise) |

| Yellow | -ve signal |

| Screen | To ground - not connected to sensor body |

Ordering Codes & Options

| Core Product | Capacity (inc Engineering Units) | Cable Length (m) | Specials Code | Result |

|---|---|---|---|---|

| DTD-P | 10Nm | 003 | 000 | DTD-P-10Nm-003-000 |

| DTD-P | 20Nm | 003 | 000 | DTD-P-20Nm-003-000 |

| DTD-P | 50Nm | 003 | 000 | DTD-P-50Nm-003-000 |

| DTD-P | 100Nm | 003 | 000 | DTD-P-100Nm-003-000 |

| DTD-P | 200Nm | 003 | 000 | DTD-P-200Nm-003-000 |

| DTD-P | 250Nm | 003 | 000 | DTD-P-250Nm-003-000 |

| DTD-P | 500Nm | 003 | 000 | DTD-P-500Nm-003-000 |

| DTD-P | 1000Nm | 003 | 000 | DTD-P-1000Nm-003-000 |

| DTD-P | 2500Nm | 003 | 000 | DTD-P-2500Nm-003-000 |

| DTD-P | 5000Nm | 003 | 000 | DTD-P-5000Nm-003-000 |

| DTD-P | 10kNm | 003 | 000 | DTD-P-10kNm-003-000 |

Case Studies

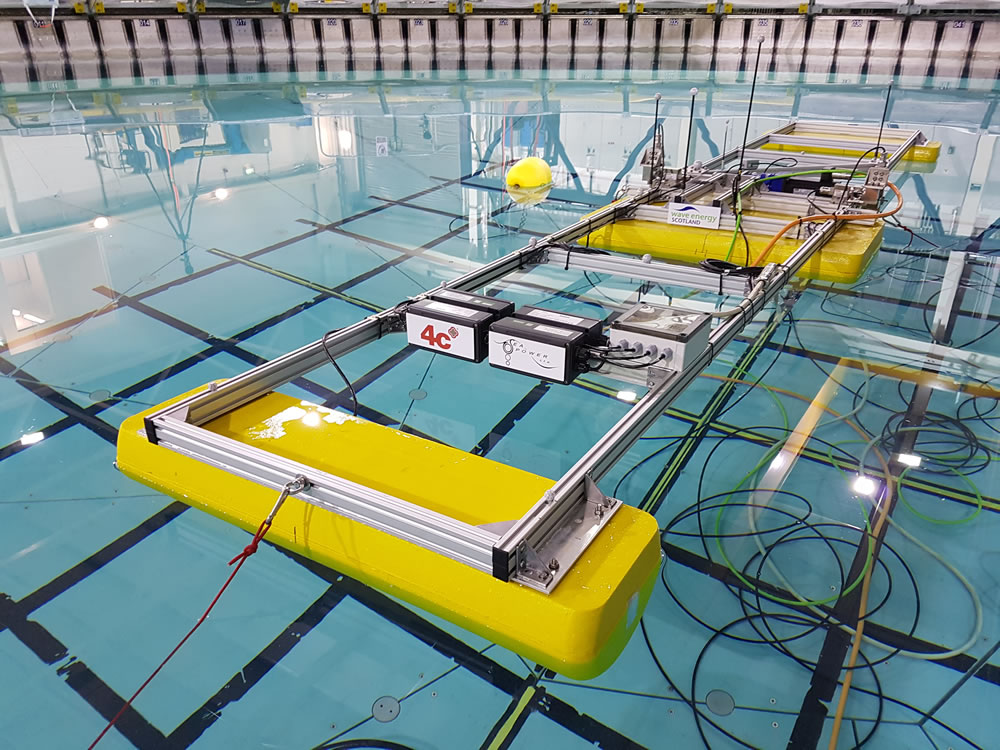

Real Life: Power Take-Off Torque Monitoring – Accurate, Fast and Simple!

Read the real life case study of power take-off torque monitoring on the Wave Energy Converter The SeaPower Platform. See how our complete torque measuring system enabled engineers to accurately monitor the torque applied by the Wave Energy Converter as it responded to waves in the test tank with accurate, fast and reliable results.