At a Glance

- Capacities: 0-250kg up to 0-2000kg

- Output: 2mV/V

- Environmental Protection: IP67

- High Accuracy: <±0.025%/RC

- Optional Mounting Accessories

- Optional ATEX (EEx ia IIC T6)

- Optimum Accuracy Guaranteed with Shock or Vessel Mounts

- Ideal for Harsh Industrial Environments – Immersion Protected to 1m to up to 30 mins

- Optimise Signal Integrity and Reduce Noise – With our Integrated Signal Conditioning Options

- Low Cost for Price Sensitive Applications

- ATEX (EEx ia IIC T6) Hazardous Area Approvals Available

Description

Applied Measurements OSBKT single-ended shear beam load cell is suitable for medium capacity weighing applications such as hoppers and vessels where a highly accurate measurement system is required. They are also suitable for conveyor weighing applications.

The OSBKT single-ended shear beam load cell’s high integrity IP67 body and alloy steel construction make it ideal for general purpose industrial weighing applications where low-cost is a primary consideration.

Two mounting assemblies are available to suit the OSBKT single ended shear beam load cell; the Vessel Mount for static applications and the Shock / Anti-Vibration Mount for mixer, feed hopper and conveyor applications where vibration or transient loads may occur. For mount dimensions, please download the datasheet.

For hazardous environments, our OSBKT single-ended shear beam load is available with ATEX (EEx ia IIC T6) hazardous area approvals.

Technical Specifications

| OSBKT | OSBST | UNITS | |

|---|---|---|---|

| Rated Capacity (RC) | 0-250, 0-500, 0-1000, 0-2000 | 0-500, 0-1000, 0-2000, 0-5000 | kgf |

| Operating Modes | Compression Only | ||

| Sensitivity (RO) | 2.0 ±0.1% | mV/V | |

| Zero Balance/Offset | <2.0 | ±%/Rated Output | |

| Zero Return after 30 mins. | <0.025 | ±%/Rated Capacity | |

| Accuracy | <0.020 | ±%/Rated Capacity | |

| Temperature Effect on Zero | <0.0023 | ±%/Rated Output/ ˚C | |

| Temperature Effect on Sensitivity | <0.0010 | ±%/Applied Load/ ˚C | |

| Input Resistance | 380 nominal | Ohms | |

| Output Resistance | 350 nominal | Ohms | |

| Insulation Resistance | >2000@50Vdc | Megohms | |

| Excitation Voltage | 10 recommended (2-15 acceptable) | Volts AC or DC | |

| Operating Temperature Range | -20 to +70 | ˚C | |

| Compensated Temperature Range | -10 to +40 | ˚C | |

| Storage Temperature Range | -20 to +70 | ˚C | |

| Safe Overload | 150 | % of Rated Capacity | |

| Ultimate Overload | 300 | % of Rated Capacity | |

| Deflection @ Rated Load | <0.4 | mm | |

| IP Rating (Environmental Protection) | IP67 | IP68 | |

| Weight (excluding cable) | 0.9 (250kg, 500kg & 1000kg), 1.1 (2000kg), 2.1 (5000kg) | 0.9 (500kg, 1000kg & 2000kg), 1.9 (5000kg) | kg |

| Fatigue Life | 108 cycles typical (109 cycles on fatigue-rated version) | ||

| Cable Length (as standard) | 3 | 5 | metres |

| Cable Type | 6 core screened, PUR sheath, Ø6mm | ||

| Construction | Nickel Plated Alloy Steel | Stainless Steel | |

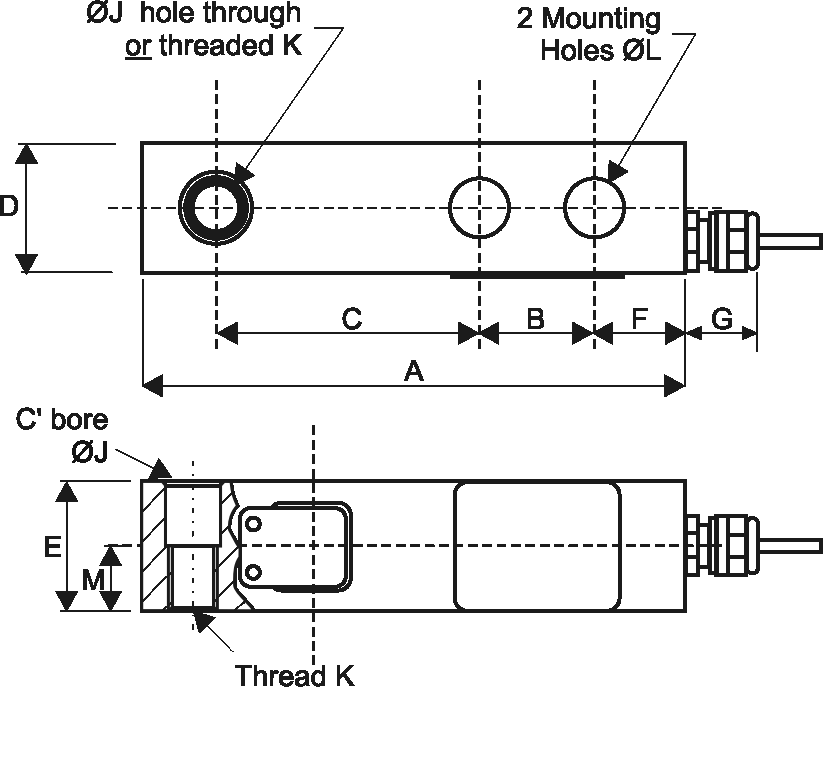

Product Dimensions

Model | Capacity (kg) | A | B | C | D | E | F | G | ØJ | K | ØL | M |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

OSBKT | 250, 500, 1000 | 130 | 25.4 | 76.2 | 30.5 | 30.5 | 16 | 19 | 13.5 | M12 x 1.75 | 13.5 | 16 |

OSBKT | 2000 | 130 | 25.4 | 76.2 | 30.5 | 36 | 16 | 19 | 13.5 | M12 x 1.75 | 13.5 | 16 |

All dimensions are in mm

Wiring Details

| Wire | Designation |

|---|---|

| Red | +ve excitation |

| Black | -ve excitation |

| Green | +ve signal |

| White | -ve signal |

| Blue | +ve sense |

| Brown | -ve sense |

| Yellow | Cable Screen - to ground – not connected to load cell body |

Ordering Codes & Options

| Core Product | Capacity (inc Engineering Units) | Cable Length (m) | Specials Code | Example Result |

|---|---|---|---|---|

| OSBKT | 250kg | 003 | 000 | OSBKT-250kg-003-000 |

| OSBKT | 500kg | 003 | 000 | OSBKT-500kg-003-000 |

| OSBKT | 1000kg | 003 | 000 | OSBKT-1000kg-003-000 |

| OSBKT | 2000kg | 003 | 000 | OSBKT-2000kg-003-000 |

Mounting Accessories

VESSEL MOUNT ASSEMBLY

- Simple to Install Into New or Existing Installations.

- Can be Installed With or Without the Load Cells in Position

- Stainless Steel Construction

- Easy Lifting and Removal of Load Cell

- Rugged Construction

- Reduces Installation Time

- Permanent Integral Safety Vessel Jacking System for your Vessel

- Anti-Lift Mechanism for Greater Vessel Stability

- Maximum Safety Protection from the Effects of Wind or Accidental Collision are Built-In.

- Heavy Duty Earth Straps Ensure that no Potential Difference Between the Upper and Lower Plates Occurs.

- Low Resistance Path Assists in Removing Strong Welding Currents.

- Substantial Protection Plate is Positioned Above the Cable Outlet to Prevent Damage by Falling Objects or Misuse.

| MODEL | OSBKT & OSBST 500-2000kg | OSBKT & OSBST 5000kg |

|---|---|---|

| A | 100 | 135 |

| B | 108 | 143 |

| C | 110 | 153 |

| D | 51 | 47 |

| E | 165 | 216 |

| F | 15 | 20 |

| G | 14 | 19.8 |

| H | 130 | 162 |

| I | 20 | 31.5 |

| J | 70 | 90 |

| K | 24 | 29 |

| L | 15 | 20 |

| M | M16 | M16 |

| N | 70 | 90 |

| O | 20 | 31.5 |

| P | 24 | 29 |

| Q | 111 | 159 |

SHOCK MOUNT ASSEMBLY

- Enables Weighing when a Vessel or Hopper is Subjected to External Forces

- Plated Steel Construction

- Minimises the Effects of Vibration

- Ease of Assembly Reduces Installation Time

- Complete Assembly is Supplied

| MODEL | OSBKT & OSBST 500-2000kg |

|---|---|

| A | 146 |

| B | 110 |

| C | 70 |

| D | 24 |

| E | 130 |

| F | 165 |

| G | 20 |

| H | 14 |

| I | 20 |

| L | 220 |

| M | 180 |

| N | 146 |

| O | 24 |

| P | 26 |

| Q | 18 |

| R | 106 |

| S | 30 |